Closed Enrollment

Published Course

ReCon HVAC

ReCon HVAC

About this Course

How familiar are you with your plant's HVAC system? In this course you will learn the basics of HVAC system components, as well as the detailed aspects such as psychometrics, air pressure, economizers and chillers. Often times these systems are hidden from sight so we don't think much about them, but through hands on activities such as diagraming your plant's HVAC system, and learning to use tools such as MEASUR and how to read a psychrometric chart, ReCon leaders will be able to bring easy fixes to their plants, as well as plan for larger, long-term improvements to the plant.

Course Features

-

100%

Accessible from any device

-

Self Directed

Learn with a cohort but when it fits your schedule

-

On-demand Video

Interactive video lessons

-

PepsiCo Internal Expertise

Brought to you by Global Sustainability Operations

What You Will Learn

- HVAC Controls and Automation

- Deeper understanding of Air Balance

- How to Increase Efficiencies and Maintenance Practices

- How to read Psychrometric Charts

- How to calculate Air Changes

- Funding opportunities for Plant Improvement

Course Overview

9 Lessons

36 Activities

7 Discussions

2 Live Events

Welcome

-

Kick-Off

-

Attend: Kickoff Call

-

Join this kickoff call to learn about:

- Welcome to the course!

- What to expect in the course

- Using MEASUR

- Completing exercises

-

-

Getting Started

-

Complete or Update: Profile

-Take a few minutes to update your profile if needed with any new role, plant, or hobbies so your cohort can get to know you!

-

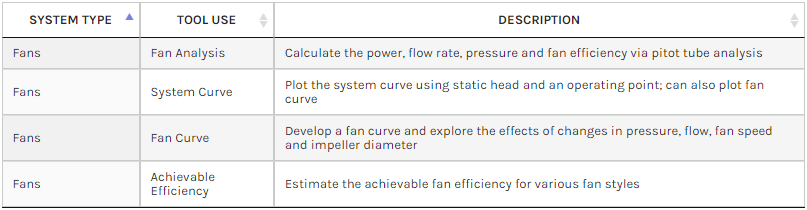

Download: MEASUR

-Take this time to download the MEASUR tool and explore some of the options. See the guide attached for information on how to download it.

Pay particular attention to the Fans tools.

-

Discuss: ReCon Tactics

-There are three ReCon Tactics:

- Do it not: Turn equipment off when not needed

- Do it less: Reduce load, turn up the thermostat, economize

- Do it better: Efficient equipment, centralized controls

Thinking about the HVAC system in your plant, what barriers do you see to accomplishing any or all of these tactics?

-

Watch: HVAC Fundamentals - Optional

-If you would like a comprehensive overview of the HVAC system basics, take a look at this video by the Engineering Mindset. The video provides an overview of a typical system and includes real-world examples.

-

HVAC Systems

-

HVAC Components

-

Read: Importance and Savings Potential

-About HVAC

Here are a few reasons why HVAC is important:

- Comfort

- Productivity

- Air quality and health

- Product quality

HVAC energy is used in:

- Fans

- Pumps

- Conditioning of outside air

- Internal loads (cooking, equipment, computers, lights)

- Envelope loads (walls and windows)

HVAC Savings Potential for Frito-Lay/Quaker

Here is an example of what a small 15% improvement in energy costs per plant can mean for PepsiCo.

- The annual cost of electricity for plants: $40,000,000 per year

- HVAC electrical usage: 10% – 25% of plant's usage

- Average savings per plant: 15%

- Potential for company-wide plant HVAC savings: $1,000,000 per year

Sources of Savings

- Low-cost O&M measures or equipment upgrades

- Retrocommissioning

- Reprogramming of control systems

- Replacement of starters with variable speed drives

- Conservation measures that require capital investment

- Replace with more efficient equipment

- Install centralized control systems

- Fundamental changes to providing plant HVAC requirements

- Replace multiple packaged roof-top units with chilled water systems

- Lower maintenance costs

- Improved flexibility for upgrades

- Reduced energy usage

Act as an owner by identifying even the smallest changes you can make to save energy. Little changes can add up to large savings!

-

Watch: How Chillers, AHUs, and RTUs Work

-Look at this video by the Engineering Mindset. Learn about how chillers, cooling towers, air handling units, RTUs, and other tools work together in central plant HVAC systems.

-

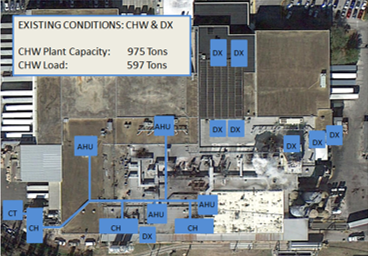

Exercise: Diagram

-Diagram your plant’s HVAC system. Include the locations of chillers, air handling units, exhaust fans, large processing stacks, and rooftop units. Prepare to submit either a drawing or photographs (check with your plant manager about using photos). Use the discussion on this page to ask any questions or express any concerns. You will have additional time tomorrow to finish up and submit your diagram.

Suggestion: Use Google Maps to locate an aerial photo of your plant, put that photo on a PowerPoint and mark it up as needed. See the example below.

-

-

HVAC Components in Your Plant

-

Upload and Discuss: Your Plant's HVAC System

-Submit either a drawing or photographs (check with your plant manager about using photos) of your plant's HVAC system. Describe your experience locating all the elements and any discoveries you made of possible efficiency improvement ideas.

-

-

Psychrometrics

-

Watch: What Psychrometrics Can Do for You

-In this video, Jose de la Portilla, a technical training manager from Lennox Learning Solutions, explains what a psychrometric chart does and how it can help determine HVAC system efficiency. While this is geared toward residential systems, the chart and efficiency measurements also apply to plants.

-

Watch: How to Read a Psychrometric Chart

-This podcast from Titus Timeout provides an overview of how to read a psychrometric chart.

-

Download and Read: Psychrometrics

-A psychrometric chart is used to study energy in the air.

It helps you understand:

- The components of energy in the air

- Where energy is used in HVAC

- Required conditions in your plant

- How your local climate impacts HVAC

Download the attachment for a more detailed walk-through with specific examples.

-

Watch: Psychrometric Chart Cooling and Dehumidification

-To learn more about the psychrometric process of dehumidification and cooling, watch this video by Insight Partners as they review more tips on how to read a psychrometric chart including dry-bulb temperature and the humidity ratio.

-

Watch: Simple Heating

-This video shows how to determine the energy used in a heating example by using a psychrometric chart and the associated calculations.

-

Download: Blank Psychrometric Chart

-Download a blank psychrometric chart below. In the next exercise you will use the chart to plot conditions at your plant.

-

Complete: Psychrometric Chart Exercise

-Plot the conditions at your plant on the psychrometric chart you just downloaded and upload it (or a photo of it) to the discussion below. What did you discover as you completed the exercise?

-

-

Air, Pressure, Processing, and Packaging

-

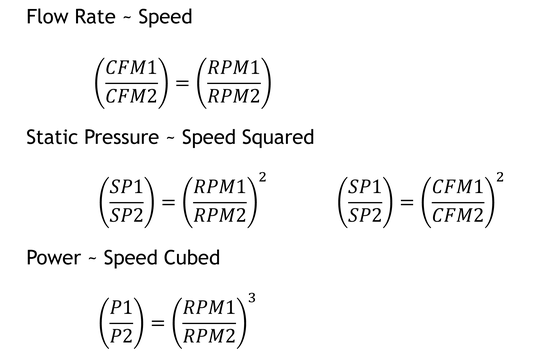

Download and Read: Fans and Pumps

-How much do you know about the fans and pumps in HVAC systems? Take a look at the calculations in the diagram below. Then, walk through the download to learn more aspects and details of the fan curve. For additional information, revisit the Fan calculations that MEASUR offers.

-

Watch: Positive and Negative Pressurization

-This Titus Timeout podcast episode discusses positive and negative pressurization of a space or a building.

-

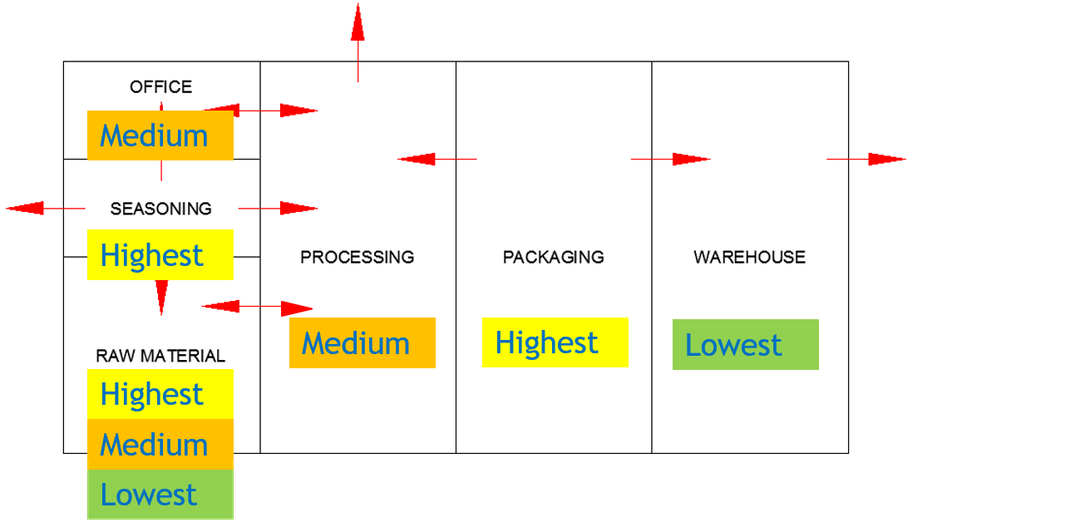

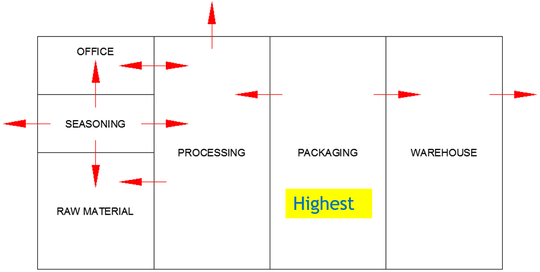

Read: Pressurization

-Positive pressurization is about control.

- Control of the temperature

- Humidity control

- Control of contaminants

Negative pressurization introduces uncontrolled air, which is unfiltered and unconditioned. The amount of pressurization affects comfort and product quality.

High-Pressure Spaces

Air flows from high-pressure spaces to lower-pressure spaces. The highest-pressure spaces are reserved for critical conditions and should be sealed against penetrations from other spaces.

Medium and Low-Pressure Spaces

These are used for less critical conditions. An example of how different pressurizations may be used in a plant is below. The key point is to use the least pressure that maintains comfort and the quality of the product.

Next, we'll take a look at air exhaust and make-up air in processing.

-

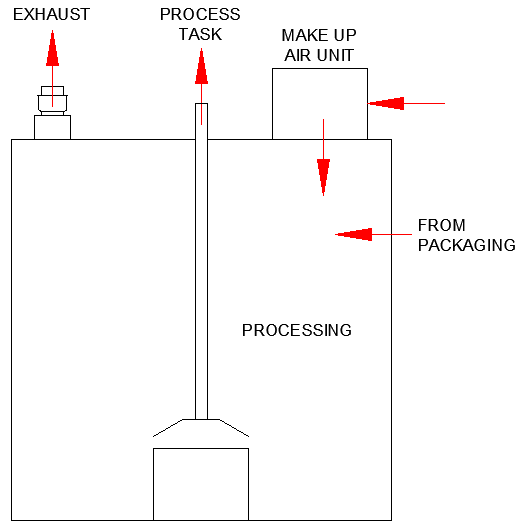

Read: Processing

-In this section we will take a look at the processing areas of your plant, especially exhausting air. The exhaust system plays a role in contaminant control, air quality, occupant comfort, and pressurization, which you just learned about. To be efficient, you want to exhaust the minimum amount of air that meets these conditions.

Below is a diagram of the typical ventilation layout of the process kitchen.

For efficiency, you want to control the exhaust and makeup air (MUA) amounts and the number of air changes per hour to save fan power and the conditioning of the makeup air.

Take a look at the below example and how they show the difference adjusting the airflow makes in annual power usage. These assume that there are eight 10-HP exhaust fans with the capacity to move 20k cubic feet per minute (CFM) each, or 160k CFM total. The makeup air is brought in using two 50-HP fans, with the capacity to move 180k CFM. The process exhaust fan moves 20k CFM.

Existing Energy Usage:

For this example, the fan motors are 80% loaded at full speed.

Exhaust Fan Power = 8 x 80% x 10 HP x 0.746 KW/HP = 48 KW

MUA Fan Power = 2 x 80% x 50 HP x 0.746 KW/HP = 60 KW

Total Power = 108 KW x 8,760 Hrs/Yr = 946,000 KWH/YrUsage After Implementation:

Reduce exhaust air flow to 100,000 CFM by turning off 3 exhaust fans.

Reduce MUA air flow to 120,000 CFM by slowing fans with a variable flow device (VFD).Exhaust Fan Power = 5 x 80% x 10 HP x 0.746 KW/HP = 30 KW

MUA Fan Power = 2 (120/180)2 x 80% x 50 HP x 0.746 KW/HP = 27 KW

Total Power = 57 KW x 8,760 Hrs/Yr = 499,000 KWH/YrFan Savings

Annual savings = 447,000 KWH/Yr * $0.06/KWH = $27,000 (this is assuming the electrical cost is $0.06/KWH and your cost may be different)

-

Read: Packaging

-Savings Opportunities for the Packaging Areas of the Plant

- Raise temperature settings

- Maintain positive pressure

- Convert to single zone variable volume

- Economize

- Improve equipment efficiency

Let's take a look at each of these individually.

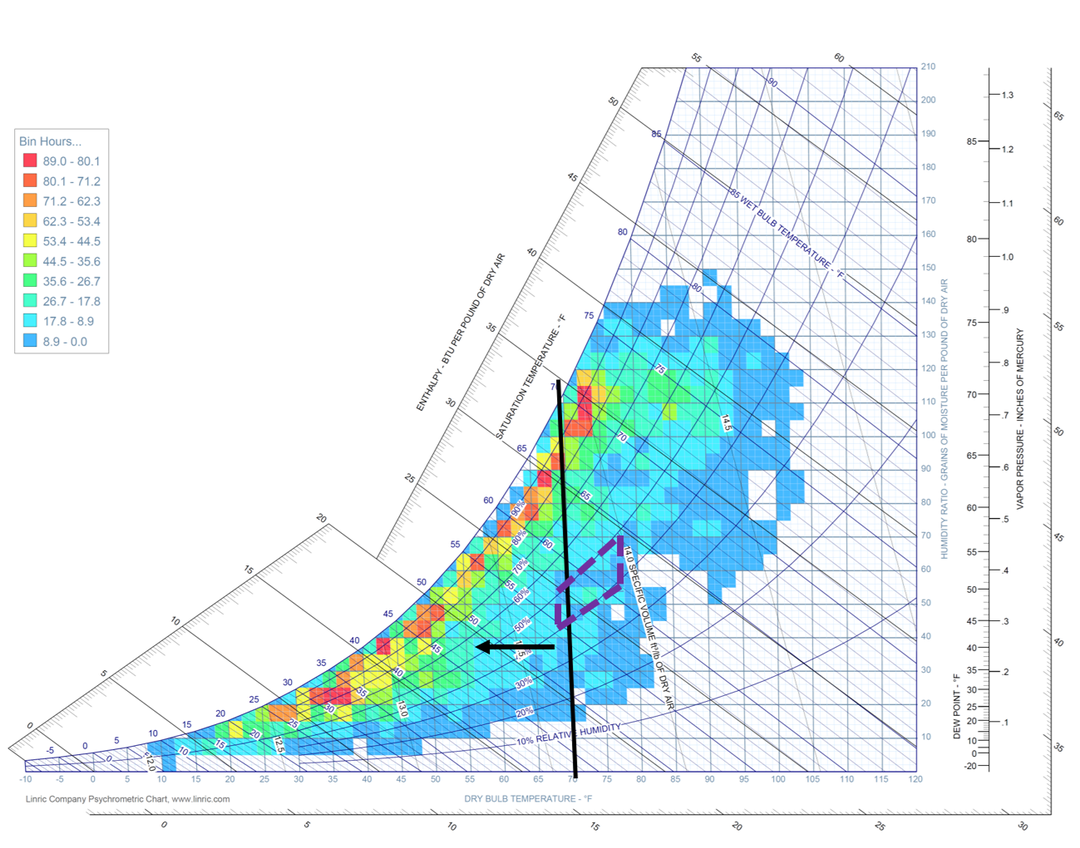

Raise Temperature Settings

- Increase settings to the high end of the acceptable range – 78 degrees at 50% RH.

- Understand that cooling equipment operates more efficiently with warmer return air.

- Increase the available hours for economizing.

Maintain Positive Pressure

Why?

- Maintain conditions and quality

How?

- Minimize OA required to maintain pressure

- Seal space to the extent possible

- Introduce OA at AHU

- Transfer from an adjacent space

- Measure and control with a differential pressure sensor

Convert to Single Zone VAV

In the next few diagrams we will walk through converting to single zone VAV.

- Reduce air flow to the minimum required to satisfy the temp setpoint

- Save fan energy and improve dehumidification

Challenges and Opportunities with DX RTU

- Reducing air flow can cause the evaporator coils to freeze up.

- Careful coordination with the existing packaged unit manufacturer is required.

- May be able to reduce the fan speed/CFM but leave the unit at a constant volume.

- Install a variable volume packaged RTU when existing equipment is replaced.

-

Watch: Air Change Per Hour Calculation

-Take a look at this video by VRF Wizard to learn more about calculating air changes per hour. Take notes for an exercise you will be completing tomorrow.

-

Exercise: Pressure Map

-Pressure map your plant. Which areas have positive pressure and which ones have negative pressure? If in doubt, hold a piece of tissue or other paper in the doorway to see which direction it is pushed. In the discussion box below, share your results and what changes you can make to save energy. Review other plants’ answers to see if there are additional actions you can take.

-

-

Economizers and Chillers

-

Watch: HVAC Economizer Fundamentals

-Take a look at this video by TecTube explaining what economizers look like, what pieces are involved, and how they function.

-

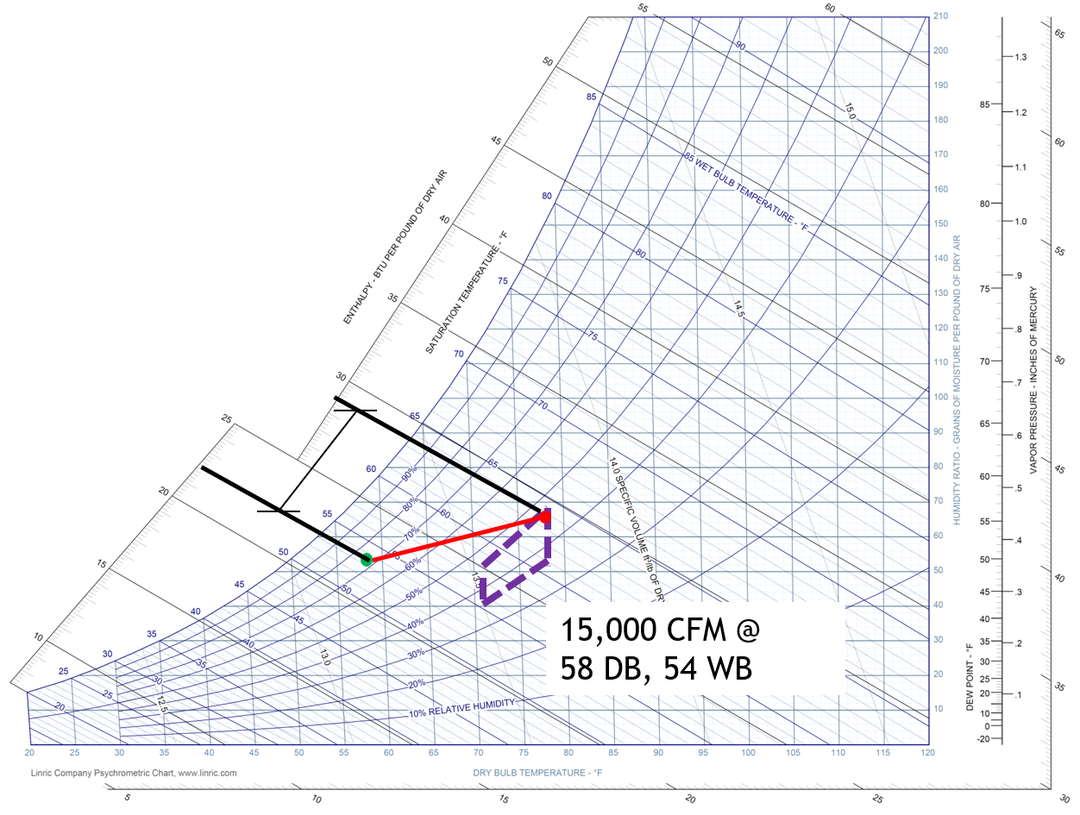

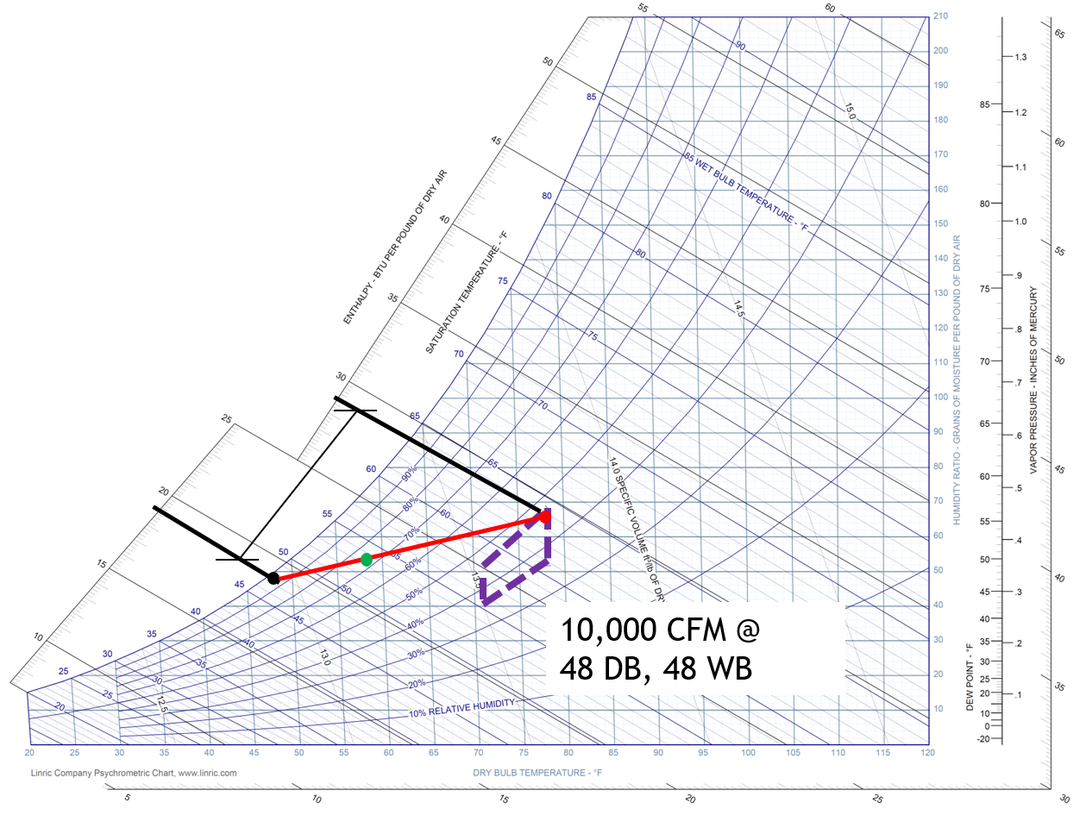

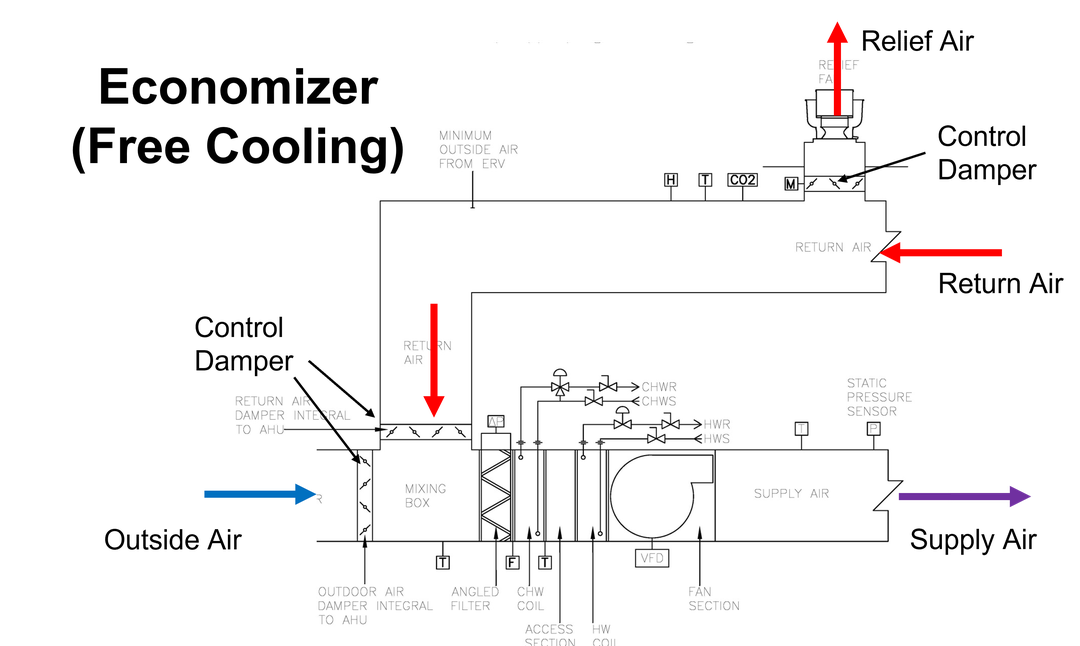

Read: Packaging Areas

-Let's take a closer look at economizers in packaging. Below is a diagram of an economizer free-cooling system. Continue reading for scenarios and how to improve efficiency.

When can you economize?

The next few diagrams cover various economizing scenarios.

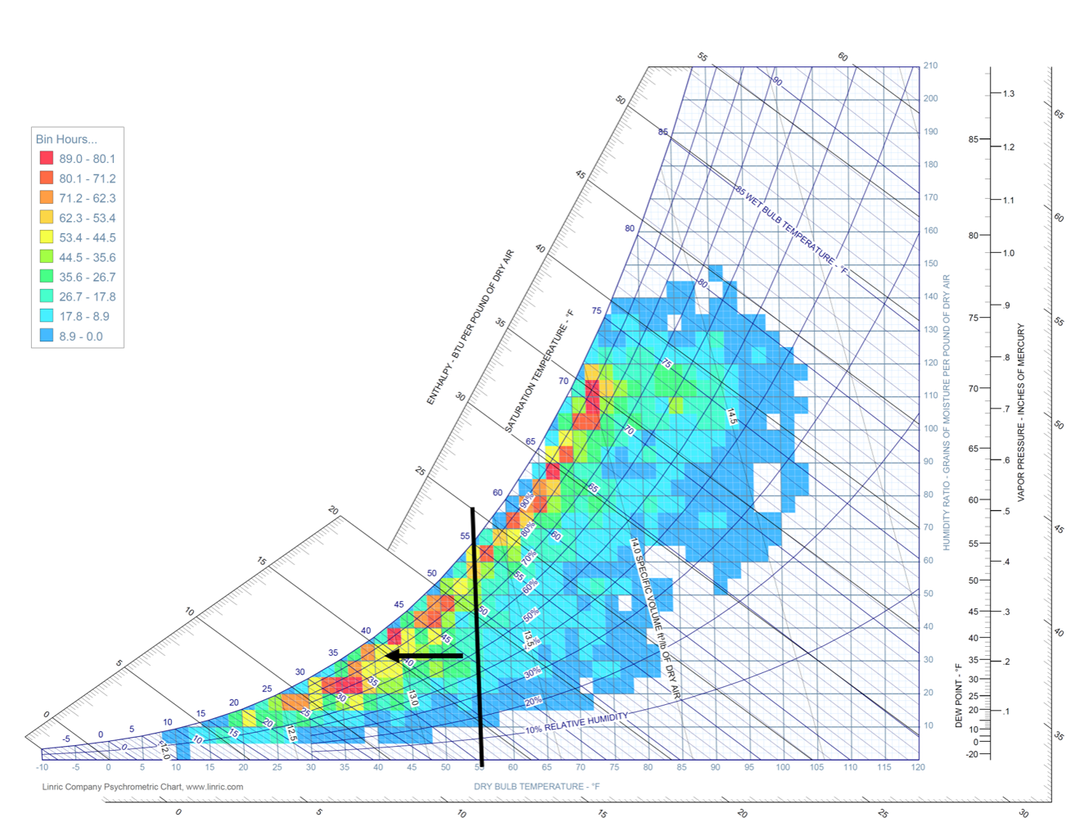

1. Full Economizer

When the OA (outside air) temperature is lower than the desired discharge air temperature (below 55F)

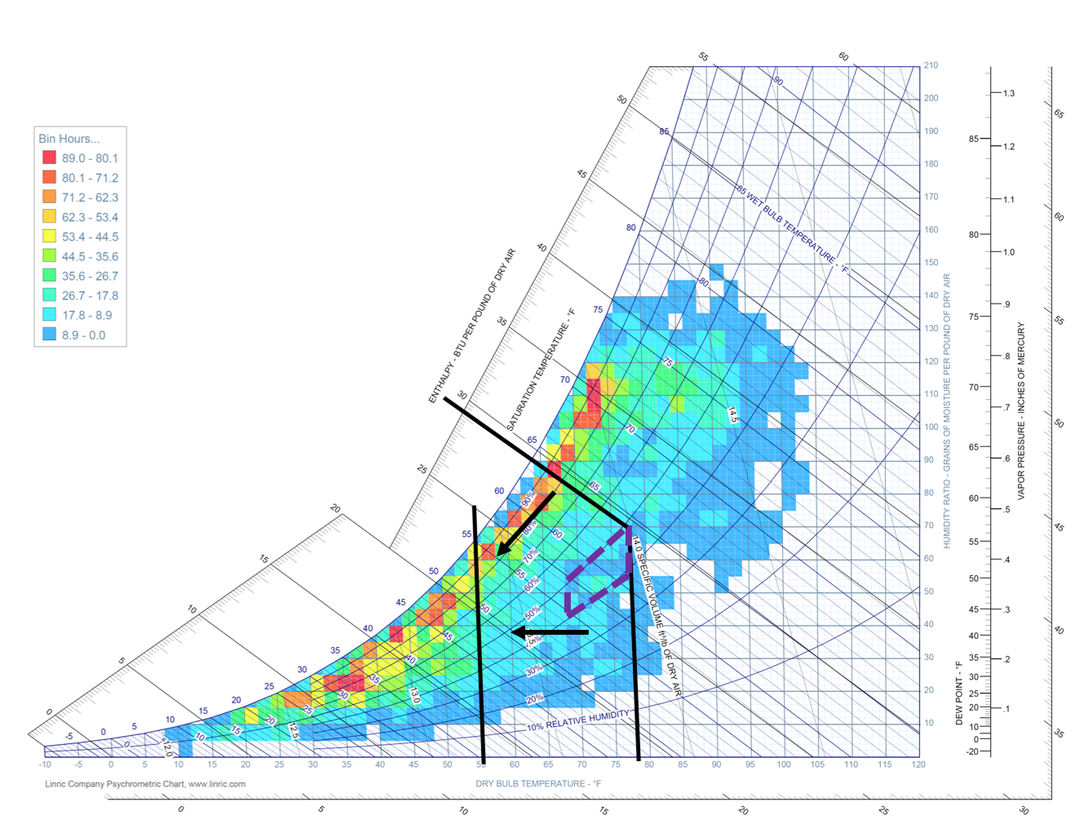

2. Enthalpy Economizer

Whenever outside air enthalpy is lower than the return air enthalpy. Requires DB and WB sensors.

3. Simplify

Simplify control and capture most of the available hours with a dry-bulb (temperature) economizer

Economizer Summary

- Reducing airflow can cause the evaporator coils to freeze up

- Careful coordination with the existing packaged unit manufacturer required

- May be able to reduce fan speed/CFM but leave the unit at a constant volume

- Install variable volume packaged RTU when the existing equipment is replaced

How to Improve Equipment Efficiency

- Serve from the central chiller plant

- Higher efficiency RTU

- Variable volume for a single zone

- Evaporative condenser

- Centralized HVAC controls

-

Read: Office Areas

-Characteristics

- Comfort conditioning

- Variable occupant load

- Always air-conditioned

- Different system types – packaged RTU, constant volume, variable volume (VAV), perimeter heat

Savings Opportunities

- Adjust temperature settings

- Setback when possible

- Convert to variable air volume (VAV)

- Economize

- Improve equipment efficiency

- VFD on the fan motor

- Heat recovery from exhaust

- Upgrade HVAC Controls

HVAC Control Strategies

- Static pressure reset on VAV system

- Slow fan down so that critical zone is barely satisfied (VAV box at 100% open)

- Provides fan energy savings

- Discharge air temperature reset

- Increase AHU discharge air temperature

- Based on OA temperature or critical zone

- Provides reheat savings

- Control schedules zone-by-zone

- Economize

- Demand control ventilation (DCV) CO2 sensors in variable occupancy spaces

-

Watch: Free Cooling Chillers

-How much do you know about providing cooling to HVAC systems? Take a look at this video by TecTube to learn more about the cooling needs and requirements of HVACs and ways of efficiently providing cooling.

-

Read: Central Chilled Water Plants

-

Now, we will explore efficiencies for central chilled water plants. Components to consider include:

- Water-cooled chillers

- Pumps with variable-speed drives

- Cooling towers

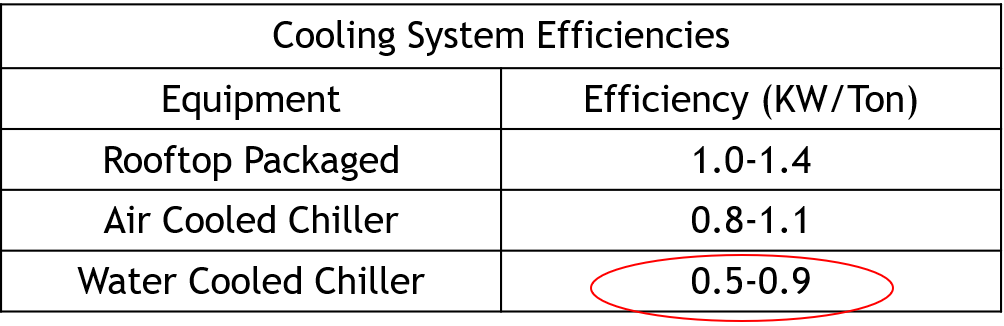

Below is a table of various cooling system efficiencies based on the equipment type. Does anything surprise you?

Advantages

There are several advantages for central chilled water plants, such as:

- Scalable

- Provides redundancy

- Energy efficient

- Easily controllable

- Long life

- Low maintenance

Here are some additional opportunities to consider:

- Energy-efficient motors

- Heat recovery

- Evaporative cooling

Disadvantages

There are also a few potential disadvantages to consider, such as a high initial cost and the required space for the equipment.

-

Exercise: Air Exchanges

-Yesterday you learned how to calculate how many air changes are done per hour. Determine how many air exchanges are done in different parts of your plant. Share your results in the discussion box below. What adjustments can you make to save energy while maintaining the minimum requirements as established by your local regulations?

-

-

Controls and Planning

-

Watch: HVAC Controls Automation

-In this video, Juan from Climate Tech provides an overview of HVAC control automation and walks through the hardware visually step-by-step.

-

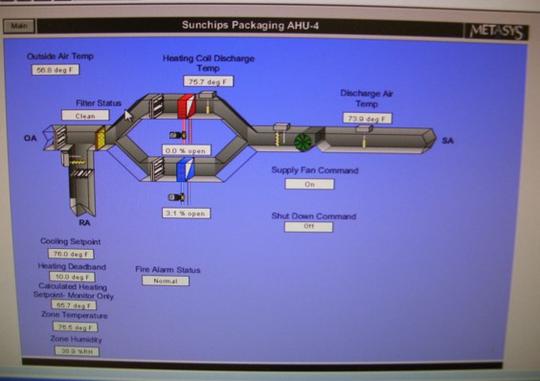

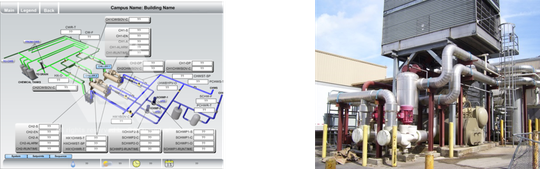

Read: HVAC Controls

-HVAC controls are often referred to as:

- Direct Digital Controls (DDC)

- Building Automation System (BAS)

- Energy Management System (EMS)

What are the benefits of a building automation system?

- Powerful control tool

- A consistent platform for all HVAC equipment

- Understandable graphic presentation

- Information is available to all users

- Flexible

- Trending and monitoring

- Troubleshooting

- Remote access

Keys to Success

- Good service from the vendor

- Well-designed sequences of operation

- Clear graphics

- Commissioning

- Training

- Can tie in all of the new equipment

- Ability to assign an “owner” of the system

-

Watch and Read: Retrocommissioning

-What is Retrocommissioning?

Retrocommissioning is the process of reviewing and adjusting system operation to:

- Check sensor calibration

- Confirm proper equipment and device operation

- Review sequence of operation

- Compare current operation to design intent

- Identify opportunities for improvement

Why Retrocommission?

- Periodic system checkups

- Identify any installation mistakes

- It is easy to overlook issues/problems when you see them every day

- Keep the control system current and relevant

- Improved operation

- Cost savings

In the below video from Michigan State University, a commissioning team reviewing the efficiency of individual building heating walks through its upgrades to the heating, ventilation, and air conditioning systems resulting in savings of 5% per building.

-

Read: Master Planning

-Actions:

- Develop an HVAC master plan.

- Create a guide to all future HVAC replacements and upgrades.

- Be proactive instead of reactive.

- Have a long-term strategy for energy, maintenance, and reliability.

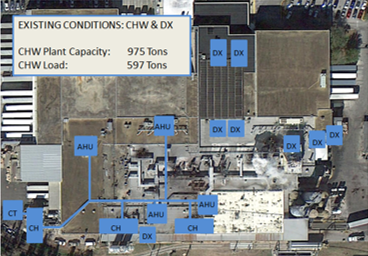

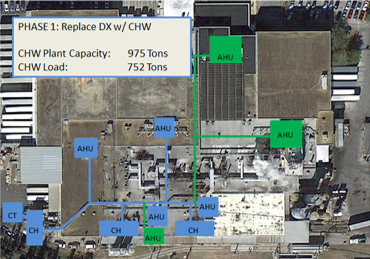

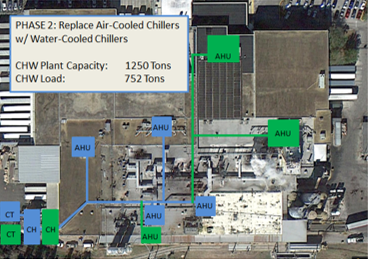

Below are some aerial images with an example of some changes a plant made:

Acronyms:

- DX = Direct Expansion Unit

- CHW or CH = Chilled Water Unit

-

Read: Plant Examples and Recommendations

-For example, take a brief look at the Perry and Orlando Plants and the efficiency changes they made.

Perry Plant

- Central CHW Plant

- Redundancy

- Reliability

- Less maintenance

- Lower energy costs

- Centralized Control System

- System optimization

- Smart control strategies

- Easy troubleshooting

- Preventative maintenance

Perry Plant Recommendations

- Retrocommissioning

- Improve control strategies

- Expand airside economizing

- Continue DX to CHW conversion

Retrocommissioning at Perry Plant

- Investigate sensors and programming

- 12 issues identified

- Specific troubleshooting recommended

- Assess existing control sequences

- 10 new strategies or adjustments recommended

- No cost / low-cost energy savings

Orlando Plant

- Centralized HVAC Control

- 7 major strategies recommended

- Convert DX to CHW

- Develop master plan

- Retrocommissioning

- 6 high-impact maintenance issues identified

- Correct installation errors

Centralizing Systems at Orlando Plant

- Centralized HVAC Control

- Variable CHW (estimated $20,000/yr)

- Pressurization control ( minimum $10,000/yr)

- 5 additional strategies ( estimated $30,000/yr)

- Convert DX to CHW

- Convert office areas (estimated $10,000/yr)

- Convert PC packaging (estimated $10,000/yr)

- Convert the seasoning area

- Central CHW Plant

-

Read: Funding

-Now that you have some ideas for how to help your plant, you are probably wondering how you can get your projects funded. Below are some tips.

- Complete an assessment of the operational cost savings

- Point out the nonenergy cost benefits

- Water savings

- Maintenance savings

- Longer-lasting equipment

- Point out the hard-to-quantify benefits

- Comfort

- Reliability

- Quality

- Leverage the cost savings against the marginal costs for upgrades

-

Discuss: HVAC Efficiency Plan

-Share your plan for increasing the efficiency of your plant’s HVAC system by listing out your short-term changes and your long-term plans. Compare your plant to others – what elements can you add to your plan?

-

-

Capstone Call

-

Attend: Capstone Call

-

This 30 minute call will conclude the course. The purpose of the call is to:

- Assess and review completion

- Check for understanding

- Answer any questions that people may have

-

• Recommended for: ReCon Leader, ReCon contact person, Maintenance Managers, Process Improvement Engineers, Regional Leaders, Project Engineers,

• Pre-requisites to take this course: ReCon Program Basics

For 2022, this course will be offered starting November 14, 2022. Register here at least a week prior to the start of the course. Please keep in mind your schedule and time commitment required prior to registration.