Closed Enrollment

Published Course

ReCon Energy in Food Processing

ReCon Energy in Food Processing

About this Course

Do you know how much energy your food lines use? In this course you will learn ways to maximize capacity of the line, the main variables on the line that impact energy production and causes of higher energy use. Through breakout sessions and hands-on exercises such as diagraming your oven or fryer and brainstorming action steps with your cohort, you’ll also learn about waste and heat loss and operations improvements tips. By the end of this course, ReCon leaders will be able to operate lines, improve settings, draft specific actions to improve their plants and spread awareness on why these practices are important more effectively.

Course Features

-

100% Online

Accessible from Any Device

-

Self Directed

Learn with a cohort but when it fits in your schedule

-

On-demand Video

Interactive video lessons

-

PepsiCo Internal Expertise

Brought to you by Global Sustainability Operations

What You Will Learn

- Line Improvement Technologies

- Surface and Piping Heat Loss

- Enthalpy and Energy Balance Overview

- Best Practices

Course Overview

7 Lessons

22 Activities

7 Discussions

2 Live Events

Welcome

-

Kick Off

-

Attend: Kick Off Call

-

Join this kickoff call to learn about:

- Introduction to the CorpU platform and how it works

- Overview of this sprint and how it fits into the stages long term

- Description of final assignment

- Open-ended poll or discussion: What's the most recent thing your plant has done for resource conservation?

-

Complete or Update: Your Profile

-Please take a few minutes to upload your picture and bio so everyone can start getting to know you. Make sure you include your current role, plant, and any hobbies. If you already have a profile, take time to make updates if needed. It's time to get creative.

-

Reflect and Select: Oven or Fryer

-Pick one oven or fryer in your plant to focus on throughout this course and type that below.

-

Energy in Food Processing

-

Energy

-

Read: Energy Balance

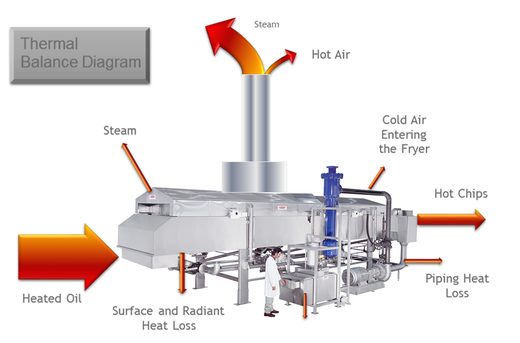

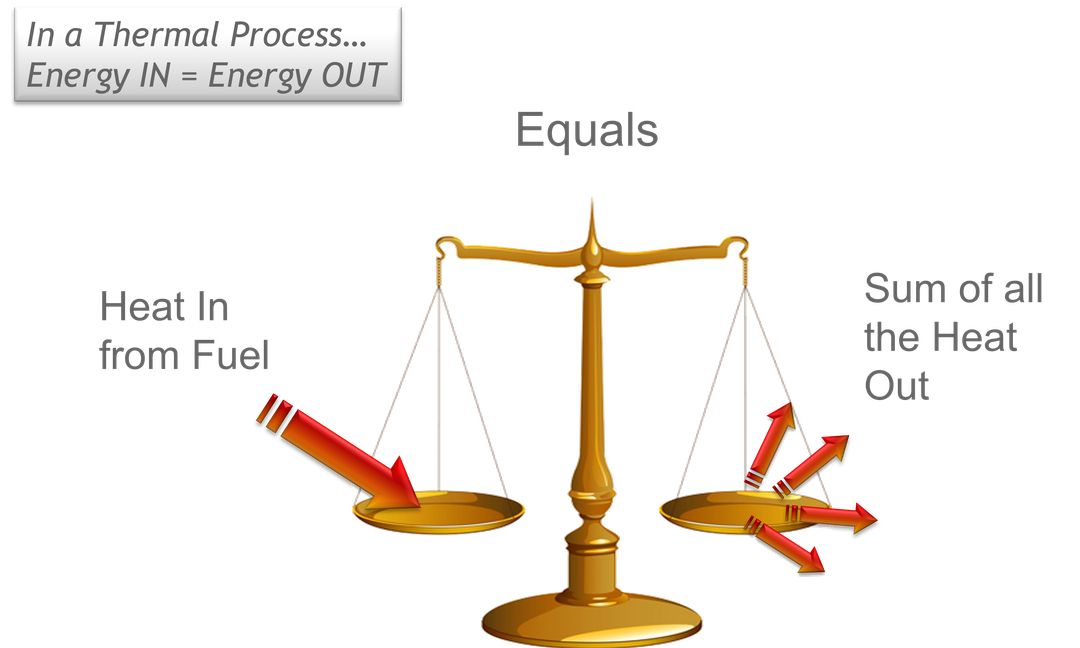

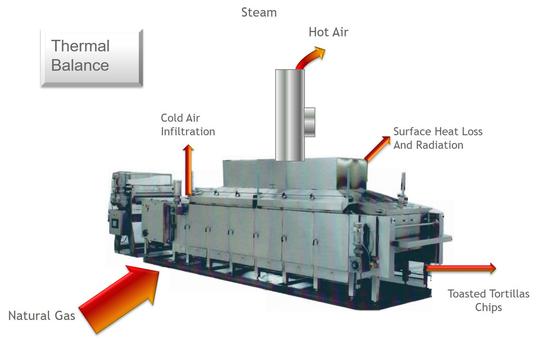

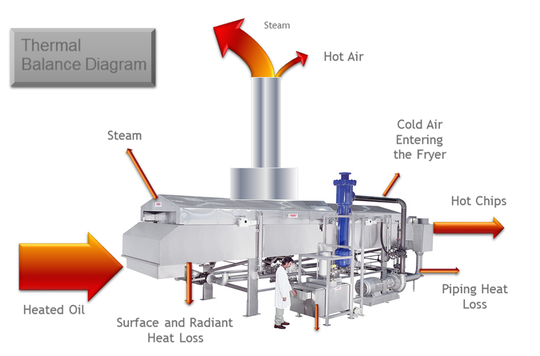

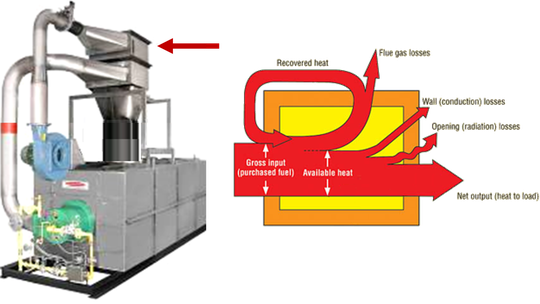

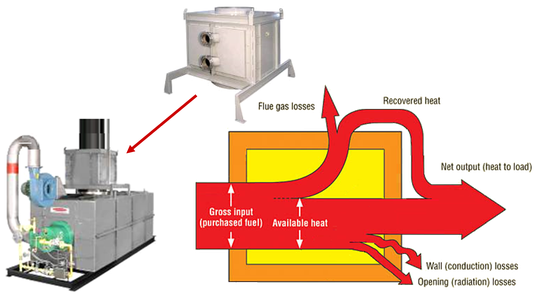

-Below are some illustrations of a key principle called Energy Balance. The Energy Balance principle states that heat input and output are always in balance.

Take a look at the scale above. On one side of the scale, we have all the heat input in the form of fuel energy. Heat is released through the combustion of carbon and hydrogen. On the other side of the scale, we have all the heat leaving the system. This includes through the chimney, along with the product, through leaks, or any other loss point.

The principle is simply that the heat leaving the system will always be the same as the heat entering the system. This key concept gives us a method of analyzing where and how heat is used. We can easily determine the heat input if we have a fuel meter, and we can calculate many of the heat outputs. We may be able to reduce costs by eliminating the losses from the heat output.

Take a look at the illustration of the tortilla chip oven below to see how the Energy Balance is at play. What goes in must come out!

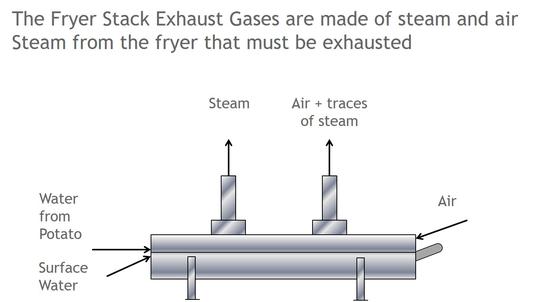

Below is another view of the principle illustrated by the potato chip fryer process.

-

Reflect: Enthalpy

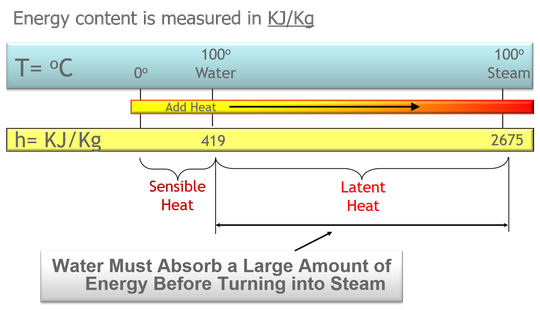

-It takes a lot of energy to convert water into steam! Let’s examine how this process happens. Take a look at the below diagram.

The blue bar on the slide represents water at different temperatures. The water is heated from 0 C to 100 C steam in increments. Then heat is added. The yellow bar displays the energy content of the water. When heated further to 100 C, the water contains 419 KJ/kg of heat energy. At this point, the 100 C water is holding as much heat as it can contain without turning to steam. Now enough heat is added to change all the water to steam. The steam has a temperature of 100 C. Notice the steam now contains 2675 KJ/kg of energy. It took a large amount of energy to change the 100 C water to 100 C steam. Steam holds a tremendous amount of energy for its weight.

Where in your plant can you see this effect? Take a few moments to reflect and answer below.

-

Read: Fryer and Oven Overview

-As an illustration of the Energy Balance, imagine a tea kettle.

For the TC line, all the water used in the kettle will require some energy to be heated. Filling the kettle with warm water will help reduce the quantity of steam required to heat it up. On the PC line, any droplets of water going into the fryer will require some energy to be evaporated. This energy is not used to transform the potato slices into chips. Additionally, this unnecessary boiling water increases the turbulence in the fryer and may impact the oil flow.

For optimum performance of the fryer, we must ensure that a minimum quantity of air enters the fryer. Here are some tips:

- Maintain the proper steam blanket

- Keep the inspection hatch on the hood closed as often as possible

- Ensure the Oil Mist Eliminator doors are well closed and hermetic

- Ensure the fryer hood is firmly closed and the water gutter is filled with water

-

Collaborate: Breakout Group Discussion

-Think of one product that your plant makes. If you throw just one unit of that product away, what are all the points where energy is now wasted? Work with the group to identify all the waste points beginning with the raw ingredients. Be as thorough as possible.

-

-

Waste and Heat Loss

-

Watch: Energy, Emissions, and Agriculture

-Watch this video on the connection between Energy, Emissions, and Agriculture!

-

Read: Waste

-Having energy-efficient equipment is only one of the elements we need to ensure good energy efficiency. Even if we reused our production waste, we will not improve our energy (GHG) footprint if we don’t tightly control it.

There is energy and carbon embedded in every raw material we use to manufacture our product. Any material that is not transformed into a finished product represents key energy loss that could have been avoided.

As we get closer to the finished product, the energy incrementally increases. Put another way, cooked potato chips will have more embedded energy than the uncooked slice, which has more embedded energy than the raw potato.

The below diagram shows the eight types of waste. Each of these types of waste that can be removed or eliminated will help not only reduce production costs but also have an impact on energy efficiency.

-

Reflect: Energy and Waste

-Thinking about your breakout group meeting where you listed everything that is wasted when one unit is thrown out, what surprised you the most about all the energy being thrown out when product is wasted? Why?

-

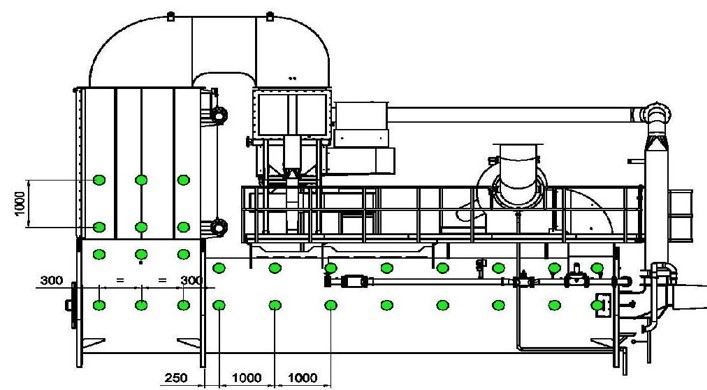

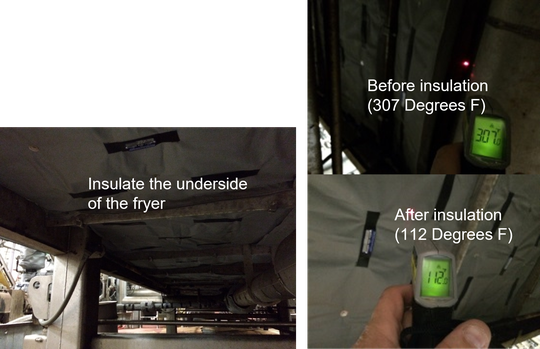

Read: Surface and Piping Heat Loss

-

Below are some tips to keep in mind for best practices to reduce surface and piping loss:

- Regularly inspect the insulation of the fryer

- Insulation should always be dry. Water infiltration negatively impacts insulation performance

- Avoid directing cold air on the fryer

- Try redirecting cold air from the HVAC unit away from the fryer

- Ensure that the insulation is in good shape on the fryer oil piping

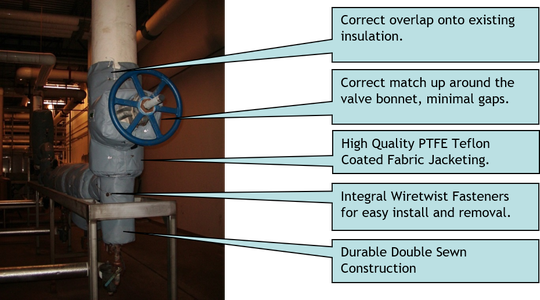

- Install removable insulation around valves and measuring device whenever possible

-

Discover and Share: Breakout Group Discussion

-Create a diagram or take a photograph (with plant permission) of your oven or fryer, marking the locations where heat/energy is lost. Submit the image using the paper clip icon below and compare it with other plants in your group using the discussion. What similarities or differences do you find?

-

-

Operations and Improvements

-

Read: Heat Exchanger

-The heat exchanger is a key piece of equipment at any plant which has significant impacts on energy usage. Below are some best practices and tips:

Tune the burner

- Maintained by qualified professionals

- Regular inspections

- 10% too much air uses up to 1.5% more fuel

Clean the combustion air filter

- Dirty filter reduces combustion air flow

- Can lead to excess-fuel situation

- If no filter, clean air control damper vanes

Maintain the insulation in good condition

Heat Exchanger Temperature Map

Best practice is to take a heat map of the surface during steady production and compare every 6 months for any degradation or hot spots.

For specific parts of the heat exchanges, there are more tips to keep in mind:

Combustion Chamber

- ON HX, check for damaged baffles (every 12 months).

- On KHX, check pollution inlet for build up of carbonized oil (every 6 months). This should be kept clean by the regular CIP.

- Check that the drain pipe is not blocked and that excess CIP is not flowing into the KHX.

Tube Bundle

- Use regular boil outs to clean the inside of the tubes.

- Tube blockages can be detected by abnormal FFA levels, loss of performance, and high pump pressure.

- If a tube blockage is suspected, check inside the headers for debris, then check the bottom of the tube bundle from inside the combustion chamber. A blocked tube will be a darker color because of overheating due to lack of oil flow.

-

Read: Operational Status

-The operational status of plant equipment can have a large impact on the plant's thermal efficiency. Pay close attention to the operations at your plant and identify any changes that arise such as:

- Kwh/kg consumption greater than usual and/or

- A longer dewatering time than usual

Potential signs of efficiency degradation:

- Slicer washer set-up might not be optimal

- Inappropriate steam blanketing or air infiltration

- Burner might need some tuning

- Potential oil polymerization in the piping

- Potential soot accumulation on the piping

If more hot fines are coming out of the fryer than usual, it could be a sign that your wash box is not running appropriately or it could be a potential slicing issue.

Remediation actions must be taken to minimize production losses and optimize thermal efficiency. -

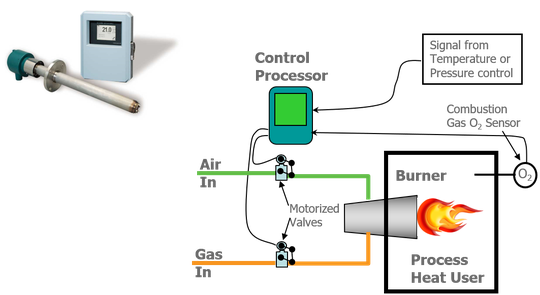

Read: Line Improvement Technologies

-Below are some tips and suggestions for line improvement technologies your plant could incorporate.

Combustion as Pre-Heat

Use the flue stack gases to pre-heat the combustion air.

Heat Exchanger Booster

Use the flue stack losses to pre-heat the oil entering the heat exchanger

O2 Trim Combustion Control

The microprocessor controller connected to an O2 meter maintains the volume of gas in proper ratio to the air volume, utilizing its internal air and gas valve characteristics.

Fryer Insulation Improvement

Increase insulation underneath the bottom of the fryer to reduce surface loss. Waterproof material helps keep the insulation dry and therefore maximizes its efficiency.

Oil Piping Insulation Improvement

Increase insulation around the valves and measuring devices to reduce surface loss. Similar to fryer insulation improvements, waterproof materials used for oil piping insulation help keep the insulation dry and therefore maximize its efficiency.

Recovery of Fryer Exhaust Heat (Steam Stack)

Heat water for building heat, sanitation, and process water generation. This saves fuel on utilities.

-

Share and Discuss: Breakout Group Discussion

-Working in your group, determine at least two things you can do in your plant in the short term to save energy and two things that are long-term projects. Complete the short-term actions in the next 24 hours. You will be discussing your actions on the next day of training.

-

-

Completed Tasks

-

Share and Discuss: Breakout Group Discussion

-Submit either a diagram, photo, or video showing the changes you made and share any observations. If needed, ask your small group for assistance in how to complete your tasks.

-

Discuss: Cohort Discussion

-What were the two things (or more) you were able to complete, and how do they compare to what your colleagues accomplished? Collect additional ideas of things you can do in your plant in preparation for an exercise tomorrow.

-

-

Best Practices and Long-term Changes

-

Read and Download: Best Practices

-By now, you have brainstormed and shared some great ideas with your breakout group and cohort to improve your plant. Take a look at the below best practices for more ideas. Download and review the Natural Gas Conservation Tips for Ovens below.

Fuel Reduction Checklist

Site

Findings in the process checklist

Consumption standardization or control parameters

Monterrey

- Basic cleaning (operational excellence)

- Standardize the burners for the bake profile

- Baking profile validation on product

- Visual diagrams were placed on boards of the 9 manufacturing lines

- Follow-up is carried out through an internal Checklist for documentation of startup times and activation of saving mode.

Obregon Biscuit

- Valve verification

- Valve verification

- Dampers al 70%

- In shutdowns longer than 4 hours, turn off the burners, turn off the extraction and close the doors to keep the heat in the oven, when turning it on again it will require less heating time

- Continuous leak inspection and correction

- Control panel filling

Below are some best practices for your PC and TC lines

Best Practices for PC

• Line thermal efficiency tracking Btu/lbs or kWh/kg by shift or in real time

• Surface moisture tracking

• Fine-tuned PC steam blanket (at each potato load change)

• Fine-tuned speedwasher/dipwasher set-up (daily)

• Heat exchanger skin temperature survey and reduction (insulation and refractory in good condition)

• Fryer insulationBest Practices for TC

• Fryer thermal efficiency tracking Btu/lbs or kWh/kg by shift or in real-time

• Oven thermal efficiency tracking Btu/lbs or kWh/kg by shift or in real-time

• Oven draft at <300% excess Air

• Oven and heat exchanger skin temperature survey and reduction (insulation and refractory in good condition)

• Fryer insulation -

Share and Collaborate: Breakout Group Discussion

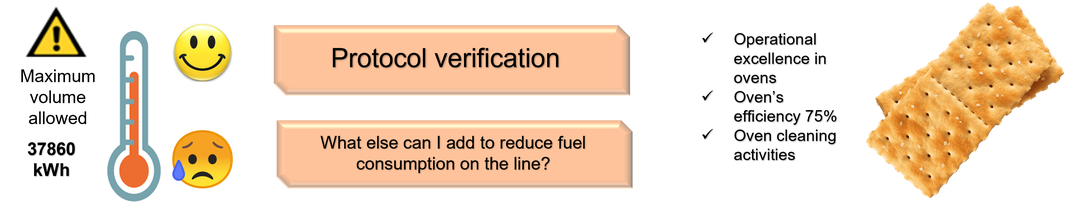

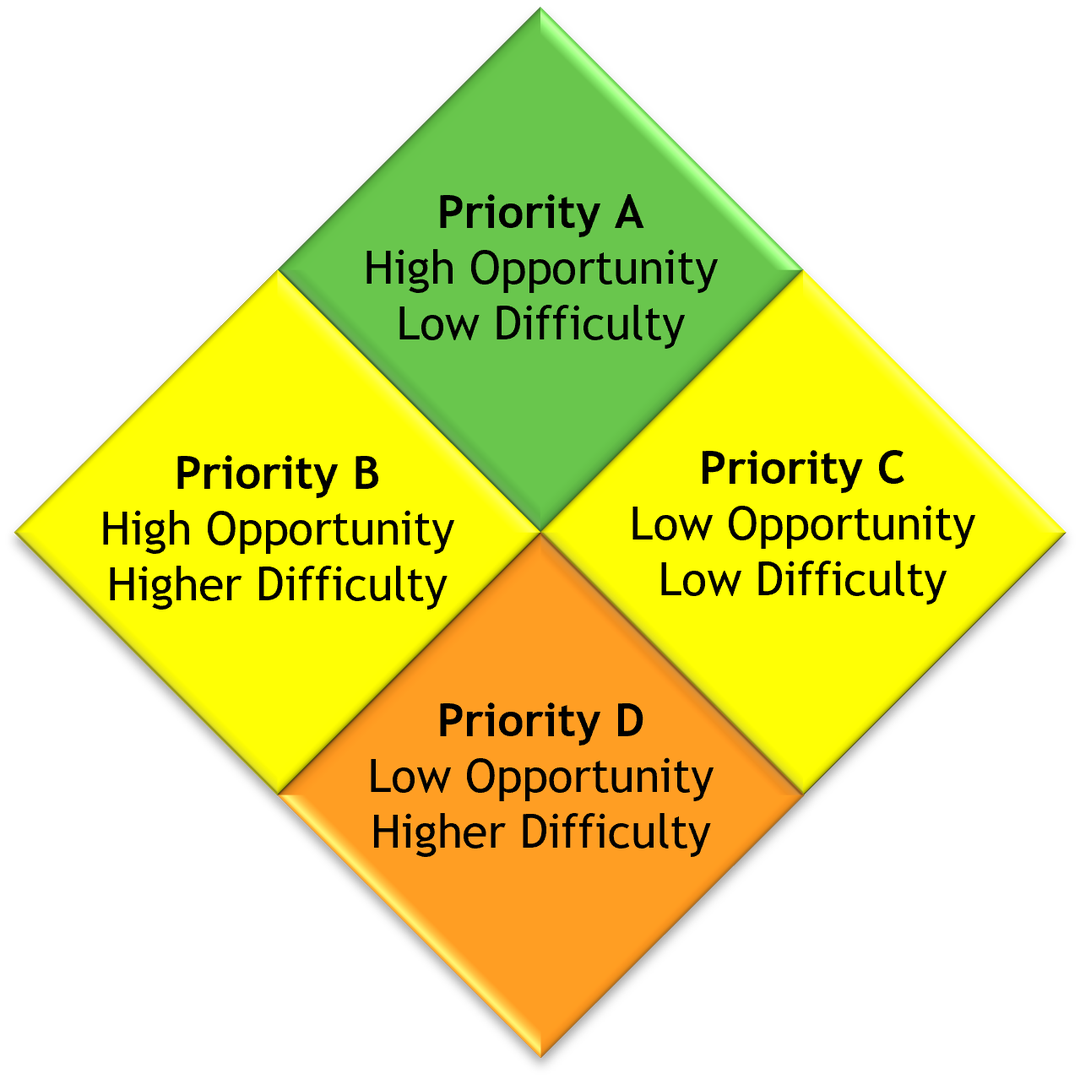

-Submit a list of longer-term changes and prioritize the list with your small group. Which items fall into the high-opportunity/low difficulty and high-opportunity/high difficulty categories as shown in the image below?

-

Discuss: Cohort Discussion

-Share some longer-term changes you can make in your plant to save energy. What barriers do you see to making those changes? Assist your colleagues with ways to overcome their barriers.

-

-

Capstone Call

-

Attend: Capstone Call

-

This 30 minute call will conclude the course. The purpose of the call is to:

- Assess and review completion

- Check for understanding

- Review and share action plans

- Answer any questions that people may have

-

• Recommended for: ReCon Point Person, Maintenance Mechanics, Process Engineers, Project Engineers

• Prerequisites for this course: ReCon Basics, GHG Fundamentals (either bev or food)

For 2022, this course will be offered starting September 19, 2022. Register here at least a week prior to the start of the course. Please keep in mind your schedule and time commitment required prior to registration.