Closed Enrollment

Published Course

ReCon and Wastewater

ReCon and Wastewater

About this Course

Do you ever consider where all the water that enters the drain goes in your facility and the costs associated with that? In this course, you will learn basic wastewater treatment principles, review the cost of wastewater treatment and develop short-term solutions for inefficiencies in your process.

Course Features

-

100%

Accessible from any device

-

Self Directed

Learn with a cohort but when it fits in your schedule

-

On-demand video

Interactive video sessions

-

PepsiCo Internal Expertise

Brought to you by the Global Sustainability Operations

What You Will Learn

- Basic principles of Wastewater Treatment Systems

- Opportunities for your Wastewater Treatment Process

Course Overview

6 Lessons

20 Activities

6 Discussions

2 Live Events

Welcome

-

Getting Started

-

Attend: Kickoff Call

-

Agenda:

- Welcome

- What to expect in the course

- Completing exercises (explain billing evaluation exercises)

-

Complete or Update: Profile

-Please take a few minutes to upload your picture and bio so everyone can start getting to know you. Make sure you include your current role, plant, and any hobbies. It's time to get creative!

-

Discuss: Cost of Wastewater Treatment

-What are all the different costs of wastewater treatment, and how will you find out the true costs for your plant?

-

ReCon and Wastewater

-

Introduction

-

Read: Introduction to Wastewater Treatment

-Depending on the sources, dissolved and suspended solids of many organic and inorganic compounds may be found in wastewaters.

Physical, biological, and chemical processes such as sedimentation or dissolved air flotation are used to remove specific dissolved matter in the wastewater.

Industrial wastewater treatment depends on the constituents in the wastewater and the goals of the treatment.

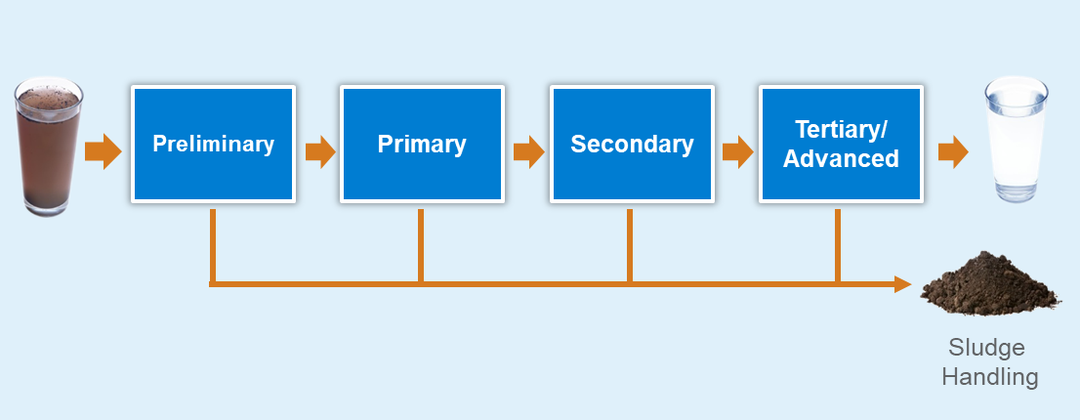

Wastewater treatment systems consist of five stages:

Preliminary treatment may involve equalization, bar screens, and/or grit tanks that remove materials that can cause operational issues and dampen the variation in flow.

Primary treatment removes most of the settleable and suspended solids from the wastewater before further treatment and may include a physical method, such as sedimentation, and/or chemical method, such as clarification by coagulation and flocculation.

Secondary treatment are biological systems used to process primary wastewater system effluent and removes over 90% of the suspended solids and other pollutants through microbiological organisms, oxygen or/and secondary sedimentation tanks.

Advanced Treatment/Tertiary Treatment is sometimes required to meet regulations to discharge water into the environment, such as removal of excess ammonia nitrogen or phosphate. Typical unit processes include, granular bed filtration, activated carbon columns, ion exchange, tertiary clarifiers and lagoons.

-

Watch: Methods of Wastewater Treatment

-Watch the video below for an overview of methods of primary, secondary and tertiary wastewater treatment and more details on the purpose of each stage of treatment.

-

Read: Sludge

-Sludge is a by-product when wastewater is treated.

Sludge thickening and dewatering are two related, equipment-intensive operations designed to separate water from solids:

The major difference between thickening and dewatering is the amount of water separation achieved in each process.

Sludge disposal is usually calculated by volume and/or weight, thus removal of water from sludge will reduce the disposal costs.

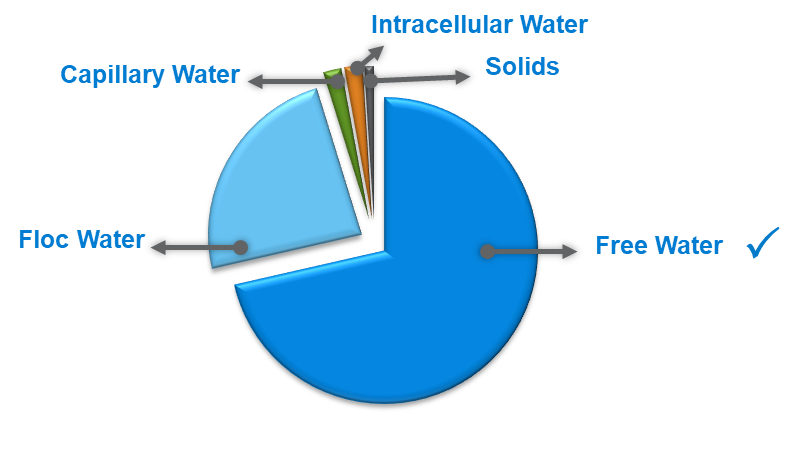

Water in sludge can be classified into:

Approximately 70% of the volume is formed by free water in a typical waste activated sludge. Free water is present in the bulk fluid.

In a typical waste activated sludge, approximately 25% of the volume is floc water. Floc water surrounds the floc but is not attached to the solids.

2% of a typical waste activated sludge is capillary water. Capillary is held onto solids by capillary action and is not easily removed from sludge without chemical treatment.

In a typical waste activated sludge, 2% is intracellular water. Intracellular water is the portion of water found inside bacterial cells and cannot be removed unless the cell walls are lysed or broken.

-

Read: Summary of Wastewater Treatment

-Wastewaters contain different types of organic and inorganic solids, both dissolved and suspended depending on the wastewater sources.

Wastewater treatment systems consist of five stages which include:

- Preliminary Treatment

- Primary Treatment

- Secondary Treatment

- Advanced Treatment or Tertiary Treatment

- Sludge Handling

There are challenges and potential cost saving in the use of water that has already been used in another application.

-

Discuss: True Cost of Wastewater

-After reviewing your invoices and utility bills, post your discoveries about what wastewater treatment actually costs your plant. Any surprises?

-

-

Wastewater Treatment Methods

-

Read and Watch: Wastewater Preliminary and Primary Treatment

-What is an Equalization Tank?

Flow equalization tanks are most often located at the wastewater treatment plant and are designed to provide storage to accommodate the variable flow into the tank and output a steady state condition that would flow into the treatment plant, which optimizes the efficiency of the treatment process.

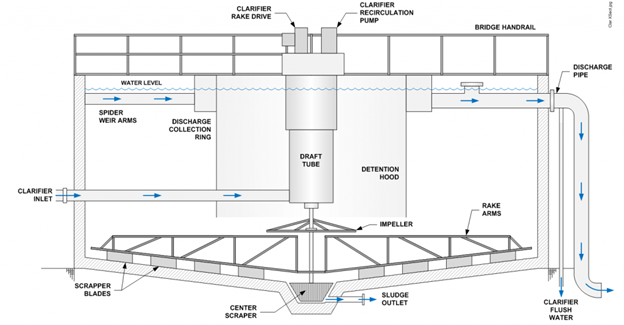

What Is a Clarifier?

You have probably heard the term clarifier, but what is a clarifier? It is a tank built mechanically that is used to remove solids coming from sedimentation.

Generally, a clarifier tank will have a built-in mechanism that can continually remove these solids. At the bottom of the tank, you can find concentrated impurities called sludge. Particles that float to the top of the tank in the liquid are called scum.

Sludge and scum can both be monitored. For example, a sludge blanket monitor will uniquely analyze your water.

These devices are circular in design for the most part but can come in other shapes and sizes depending on where you buy from. Before fluid runs through the clarifier, coagulation and flocculation occur. This causes particles to come together in clumps forming bigger particles that become more stable.

These processes can ease separation which in turn improves efficiency and conserve energy. It also helps colloids settle. The isolation of particles can also lessen the number of treatment operations that work downstream such as filtration.

During flocculation, coagulates can form denser particles. This stream runs into the clarifier to separate the liquid from solids allowing heavier and bigger particles to rest at the bottom.

Clarifiers have features that include removing solids that move slowly to lower the re-suspension of already settled solids. Liquids that are clarified filters any residue particles. That filtered liquid will then move onto the next process.

Clarifiers are often confused with thickeners because they are both used to settle solids to separate liquids and solids. It is important to understand the difference between the two.

Clarifier vs. Thickener

Visually, a clarifier and a thickener will look the same. The major difference between the two is that thickeners concentrate solids while clarifiers purify liquids.

Thickeners allow for high-density underflow, something that a clarifier cannot offer. A thickener overflow is not as clean or clear as a clarifier overflow.

Water treatment clarifiers can recover reusable process water. It also will eliminate unnecessary materials from the water. Wastewater management industries use thickeners for mineral producers.

Types of Clarifiers

The design and operation of a clarifier will be important when picking one out. The control of liquid flow should be the main thing on your mind when choosing a clarifier.

There are different types of clarifiers, some including:

- Horizontal Flow

- Solids Contact

- Inclined Surface

- Circular Solids Contact Clarifier

- Parallel Inclined Plates in a Circular Clarifier

- Tube Settlers in a Rectangular Clarifier

The different types can all keep particles out of your water that are unwanted. The difference between them is that they do the task differently.

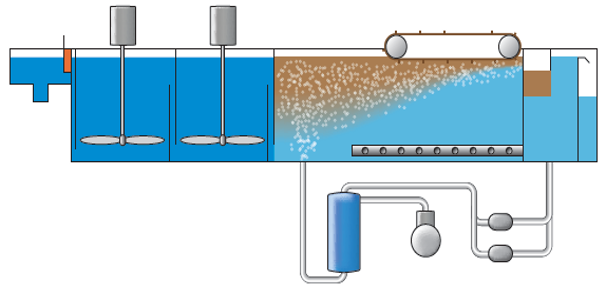

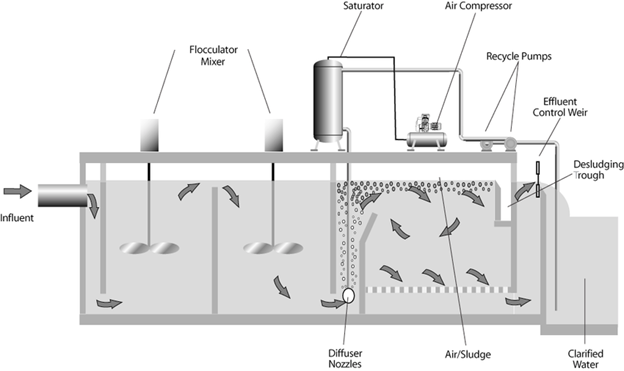

What is a DAF system?

Dissolved air flotation, the most common approach, works by attaching small bubbles of air to suspended solids. The bubbles are generated by saturating a recycled stream of water with air under pressure, then releasing the pressure rapidly to produce clouds of microbubbles.

The video below reviews how a DAF works.

-

Watch: Wastewater Treatment in Other Industries

-The video below discusses a pioneer in wastewater treatment in the pharmaceutical industry.

-

Watch: Food Factor Wastewater Treatment

-Watch the video for an example of a wastewater treatment process.

-

Reflect: Reapplication

-Now that you’ve seen how another industry deals with wastewater treatment, how do you see it applying to PepsiCo?

-

Discuss: Influencing Change

-There are many actions within a facility that impact your facility's wastewater treatment system. In your opinion, what is the best way to approach employees who do not report to you about making changes to increase awareness around wastewater treatment as well as improve water conservation?

-

Download and Review: Wastewater Treatment at PepsiCo

-Download and review the wastewater treatment solutions for different categories within PepsiCo.

-

-

Your Plant's Wastewater Treatment

-

Exercise: Water Treatment Process Mapping

-Map the water treatment process in your plant. Include every step from the point that fresh water enters the manufacturing process until it is reused and/or waste leaves the plant.

-

Discuss: Your Wastewater Treatment

-Upload a labeled picture or diagram of the water treatment process in your plant.

Now that you have read about the water treatment options for your type of plant and mapped the water treatment process in your plant, how does what you learned apply to the way your plant currently does business?

-

-

Effectiveness

-

Read: Water Reuse and Recycle

-The use of water that has already been used in other applications brings added challenges along with potential savings in water and cost.

Factors to be evaluated when planning to reuse/ recycle water include:

- Environmental and economic goals

- Quality and variability of the water source

- Quantity and quality requirements of the receiving system

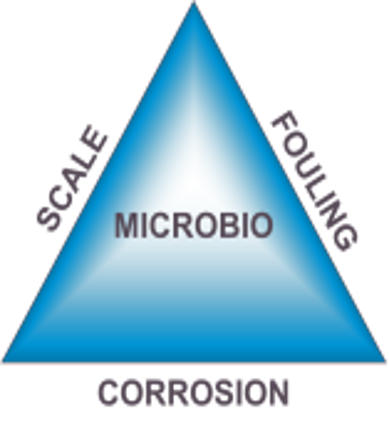

The quality of water sources is a major challenge for water recycle.

Water discharged from domestic or industrial applications usually contains higher contaminants that may cause problems in other applications as outlined below.

Additional pretreatment and process treatment may be needed to minimize problems with recycled water.

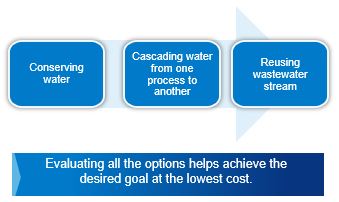

The strategy for water reuse and recycle should consider simpler options before progressing to more complex reuse and recycle methods.

-

Research and Discuss: Requirements

-Find out what the requirements are (if any) for wastewater disposal and for water reuse. Are you exceeding the requirements and less treatment will work? Do you need to improve the treatment process to be more effective? Any ideas on where less water can be used?

-

Discuss: Opportunities

-As you review the way water is used in your plant, how wastewater is treated, and if it is reused, what short-term solutions can you see that will reduce the amount of water use in your plant? Are there any opportunities operationally to reduce the amount of treatment needed? Is the wastewater treatment too much, too little, or just right for your plant’s requirements?

-

-

Capstone Call

-

Attend: Capstone Call

-

This 30 minute call will conclude the course. The purpose of the call is to:

- Assess and review completion

- Check for understanding

- Answer any questions that people may have

-

• Recommended for: ReCon Leader, ReCon contact person, Maintenance Managers, Process Improvement Engineers, Regional Leaders, Project Engineers.

• Pre-requisites to take this course: While not a pre-requisite, ReCon Program Basics is recommended prior to completing this course.

For 2022, this course will be offered starting December 5, 2022. Register here at least a week prior to the start of the course. Please keep in mind your schedule and time commitment required prior to registration.