Closed Enrollment

Published Course

ReCon Renewables

ReCon Renewables

Course Created in Partnership with:

About this Course

This course will provide organizational leaders a foundation of understanding and potentially deploying renewable energy technologies. You will learn the basic terminology of the renewable energy industry as well as gain an overview of the types of renewable energy available and fuels of the future.

Course Features

-

100%

Accessible from any device

-

Self Directed

Learn with a cohort when it fits in your schedule

-

On-demand video

Interactive video sessions

-

PepsiCo Internal Expertise

Brought to you by the Global Sustainability Operations

What You Will Learn

- Why Renewables

- Overview of Biomass, Biogas, Wind Generation, Solar and Battery Energy Storage

- Renewable Fuels of the Future

Course Overview

7 Lessons

31 Activities

5 Discussions

2 Live Events

Welcome

-

Kickoff

-

Attend: Kickoff Call

-Agenda:

- Welcome to the Renewables Course

- What to expect

- Completing discussions/active participation

-

-

Getting Started

-

Complete or Update: Profile

-If you haven't previously, please take a few minutes to upload your picture and bio so everyone can start getting to know you. Make sure you include your current role, plant, and any hobbies. It's time to get creative.

If you completed your profile earlier, take a quick look and see if there is anything you'd like to update.

-

Read: Terminology

-Before we dive into different renewable energy sources, let us review some frequently confused terms.

Weather vs. Climate

- Weather refers to atmospheric conditions that occur locally over short periods of time—from minutes to hours or days. Familiar examples include rain, snow, clouds, winds, floods, or thunderstorms.

- Climate, on the other hand, refers to the long-term regional or even global average of temperature, humidity, and rainfall patterns over seasons, years, or decades.

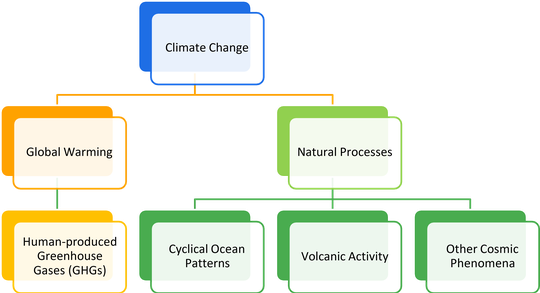

Global Warming vs. Climate Change

- Global warming is the long-term heating of Earth’s climate system observed since the pre-industrial period (between 1850 and 1900) due to human activities, primarily fossil fuel burning, which increases heat-trapping greenhouse gas levels in Earth’s atmosphere. It is most commonly measured as the average increase in Earth’s global surface temperature.

- Climate change is a long-term change in the average weather patterns that have come to define Earth’s local, regional, and global climates. Climate change is both human and naturally produced warming and the effects it has on our planet.

Greenhouse Gases (GHG) and Global Warming Potential (GWP)

- Gases that trap heat in the atmosphere are called greenhouse gases.

- Carbon dioxide (CO2)

- Methane (CH4)

- Nitrous oxide (N2O)

- Fluorinated carbons

- GWP is a measure of how much energy the emissions of 1 ton of a gas will absorb over a given period of time, relative to the emissions of 1 ton of CO2.

- Methane: 28-36

- Nitrous oxide: 265-298

- Fluorinated carbons > 1000x

Fossil Fuels vs. Renewable fuels vs. Alternative Fuels

- Fossil fuels: crude oil-derived, natural gas and coal

- Carbon-based and release GHGs when combusted or processed

- Other anthropogenic (by humans) sources: deforestation, livestock farming, landfills

- Renewable fuels: solar, wind, biomass, geothermal, hydro-electric

- Alternative fuels: nuclear, hydrogen (depends on source)

Goal: Focus on reducing GHGs from human activity to reduce global warming and reduce the human contribution to climate change.

-

Watch: PepsiCo Announces a Bold New Climate Change Goal

-Watch this video to learn more about the action PepsiCo is taking to meet climate change goals.

-

Discuss: Renewable Energy Sources

-Some PepsiCo plants may already be using renewable energy sources, and some may not. Compare your plant to others by answering the following questions:

What renewable energy sources do you currently use at your plant?

What other opportunities are there for your plant to use more (or begin using) renewable energy sources?

-

Renewable Energy Sources

-

GHG, Biomass, Biogas

-

Read: Net Zero GHG and GHG Scopes: Understanding the Drivers

-PepsiCo has ambitious goals to achieve in the coming years. This is a huge goal, broken up into three scopes.

Scopes 1, 2, and 3 add up to (net) 0.

- Scope 1 Emissions

- Process efficiency

- Onsite renewable generation

- Electrification of manufacturing/distribution

- Electrification of owned fleet

- Scope 2 Emissions

- Purchased electricity-green electrons

- Purchased heating/cooling

- Scope 3 Emissions

- Employee travel

- Electrification of non-company-owned fleets

So, how will we do all of this?

-

Watch: Carbon Credits Explained

-Let's delve into the concept of carbon credits.

What Are Carbon Credits?

1. Definition:

- Carbon credits, also known as carbon offsets, are a mechanism to reduce greenhouse gas emissions.

- They represent a unit of measurement that corresponds to one metric ton of carbon dioxide (CO₂) or its equivalent in other greenhouse gases.

2. How Do Carbon Credits Work?

- Companies, organizations, or individuals can purchase carbon credits.

- These credits are generated by projects or activities that reduce, capture, or avoid emissions.

Examples of such projects include:

- Renewable Energy Projects:* Wind farms, solar power plants, and hydroelectric dams that replace fossil fuel-based energy sources.

- Afforestation and Reforestation:* Planting trees to absorb CO₂ from the atmosphere.

- Energy Efficiency Initiatives:* Upgrading buildings, appliances, and industrial processes to reduce energy consumption.

- Methane Capture:* Collecting methane emissions from landfills or livestock operations.

- Avoided Deforestation:* Preventing the destruction of forests that would release stored carbon.

- Carbon Capture and Storage (CCS):* Capturing CO₂ emissions from industrial processes and storing them underground.

3. Verification and Certification:

- Carbon credits must be verified and certified by recognized standards and organizations.

- These standards ensure that the emission reductions are real, additional (i.e., beyond business-as-usual), and permanent.

4. Trading and Offsetting:

- Companies with excess emissions can buy carbon credits to offset their impact.

- Conversely, companies with emission reductions can sell their credits.

- The goal is to achieve a net-zero or carbon-neutral balance.

5. Challenges and Criticisms:

- Some critics argue that carbon credits may allow polluters to continue emitting without making substantial changes.

- Ensuring the integrity of projects and avoiding double-counting is essential.

6. Global Impact:

- Carbon credits contribute to global efforts to combat climate change.

- They encourage investment in sustainable practices and support the transition to a low-carbon economy.

Remember, carbon credits are just one tool in the fight against climate change. They work alongside broader efforts to reduce emissions and protect our planet.

-

Read: Carbon Credits, Certificates, and Markets

-What are carbon credits?

- A carbon credit (also referred to as an “offset”) is a certificate representing one metric ton of carbon dioxide equivalent that is either prevented from being emitted into the atmosphere or removed from the atmosphere as a result of a carbon-reduction project. When companies purchase a credit, it helps fund climate action projects that otherwise would never get off the ground, such as protecting biodiversity, preventing pollution, etc.

- Carbon credits are transferable instruments certified by governments or independent certification bodies.

- The purchaser of a carbon credit can retire it to claim the underlying reduction towards their own GHG reduction goals.

- Carbon credits can be produced by a variety of activities that reduce GHG emissions or increase carbon sequestration, e.g., renewable energy projects, carbon capture projects, etc.

Carbon Markets

There are mainly two types of carbon markets:

- Mandatory or regulatory compliance market

- Voluntary market

- The compliance market is used by companies and governments that by law have to account for their GHG emissions. It is regulated by national, regional, or international carbon reduction regimes.

- Voluntary carbon markets enable businesses, governments, universities, municipalities, and individuals to offset their emissions outside a regulatory regime.

- Trading and demand in the voluntary market are created only by voluntary buyers whereas in a compliance market, demand is created by a regulatory mandate.

The prices are governed by the supply and demand factors. Generally, the prices in the compliance markets are higher than the prices in the voluntary markets.

-

Read: Biomass Overview

-Biomass is:

- Humanity's oldest fuel

- Locally available

- Often a waste/byproduct

- Can be low cost

- Often low in sulfur, nitrogen, mercury, and other pollutants

- Lean or negative carbon intensity (when coupled with sustainable forestry and/or carbon capture/storage)

- Renewable resource

- Biomass is produced via photosynthesis

- It has always been used by humanity for food, feed, and energy

- Bioenergy resources include:

- Primary: sugar, starch, oil

- Secondary: woody, herbaceous

- Tertiary: aquatic

- Wastes: agricultural, forestry, municipal, industrial

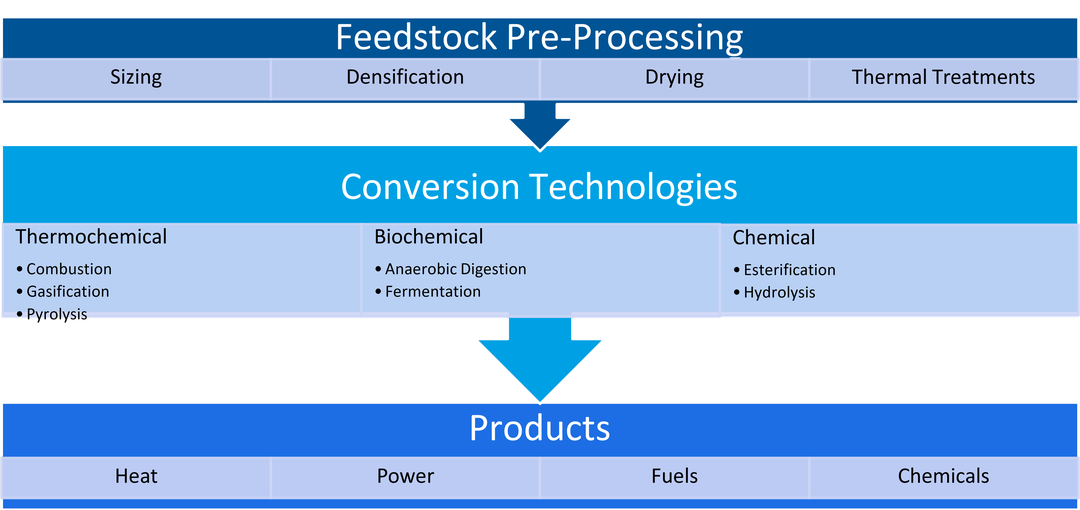

Bioenergy Conversion Processes

Political/Socio-Economic Aspects of Bioenergy

- Carbon neutrality

- Food vs. fuel

- Per unit energy emissions

- Water consumption

- Nutrient management

- Indirect land use changes

Waste Overview:

- Raw municipal solid waste (MSW) and commercial/industrial wastes can be processed into:

- Refuse derived fuel (RDF)

- Solid recovered fuel (SRF)

- Predominant type of waste will often dictate best conversion technology

- Categories of waste include:

- Recyclables: metals, glass, plastics

- Paper and cardboard

- Textiles

- Organics: food/yard waste, wood

- Electronics

- Hazardous waste

- Inerts: rocks, sand, concrete

Dispersed nature of Biomass/Waste:

- Biomass/waste collected within 50 to 100 mile radius of plant

- Usually limits plant size to 10 to 100 MW

- Implications of a smaller plant size (compared to larger fossil units) include:

- Lower efficiency

- Higher capital costs per MW

- Higher O&M costs per MWh

- Similar development costs

- Resource assessment and fuel procurement strategy are critical to financing and economic viability of project

- Countries like UK/Japan lack local resources and are importing biomass

Resource Supply Risk Factors

- Biomass/waste is a byproduct of human behavior

- Supply is often linked to the viability of other industries (e.g., forestry)

- Politics can change the resource supply and incentives

- Semi-mature markets

- Many potential suppliers

- Dynamic markets – resource assessment has a “shelf-life”

- Wide variety of chemical and physical properties

- Resource competition

- Using biomass/waste for fuel is often the lowest value use

- Contracting can be challenging

Additional requirements for sustainability can add further complications.

-

Watch: How Does Biomass Energy Work?

-The great thing about biomass energy (or simply “bioenergy”) is that its sources are plant and animal waste. So not only does biomass energy divert this organic matter from the waste stream — it turns it into something we all need, without polluting the planet. According to the U.S. Department of Energy, by 2030 the U.S. has the potential to sustainably produce 1 billion tons of bioenergy each year. As far as renewable energy sources go, biomass is not the most glamorous. But biomass energy successfully solves two major environmental problems at once — an incredible feat if there ever was one!

Watch this video by Green Mountain Energy to learn more.

-

Read: Biomass Considerations

-You have learned a little about biomass and how it's used. Let us take a look at biomass material handling, storage, waste handling, and converting the biomass fuel to heat and power.

Handling of the biomass material is based on the specific fuel. There are several aspects to handling that need to be considered:

- Transportation

- Unloading

- Stock out/storage

- Reclaim

- Processing (e.g. sizing, drying)

- Delivery to boiler

- Fire protection and dust control

The design of biomass material storage is also very important. Think about:

- Feed rates

- Storage capacity

- Geometry of the available space

If open storage is selected,

- Mobile equipment needed

- Logs vs. chips

- Automated:

- Linear Pile (Traveling Stacker)

- Radial Pile (Portal Stacker)

- Covered:

- Enclosed building/silo

- Higher costs that open piles

- Usually required for pellets

Once the biomass is used, the next issue is the waste, or Material Recovery Facilities (MRFs).

- MRFs use combination of mechanical classifiers, separators, and conveyors to separate the waste into recoverable fractions.

- Some recoverable fractions and automated technologies to recover them are:

- Fines (rotary drums)

- Ferrous metals (magnet)

- Non-ferrous metals (eddy current)

- Plastics (optical and near infrared detectors)

- MRFs can also include biological treatments (MBT facility) to further process or stabilize the organic/biodegradable fraction, which include:

- Compost (aerobic stabilization)

- Waste fuel/SRF (bio-drying)

- Biogas (anaerobic digestion)

Conversion technologies are also important.

- Thermochemical Conversion

- Direct Combustion

- Gasification

- Pyrolysis

- Biological Conversion

- Anaerobic Digestion

- Anaerobic Biodegradation in Landfill

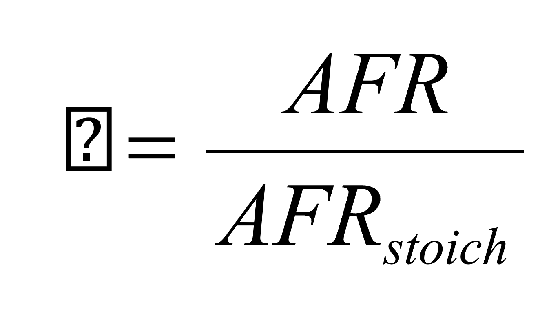

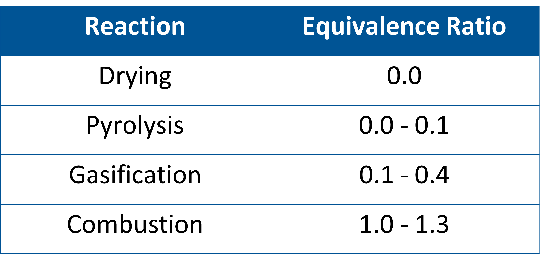

Equivalence Ratio

Equivalence ratio is defined for oxidation reactions as the quotient of air-to-fuel ratio (AFR) for the process to the AFR for complete combustion (stoichiometric).

The characteristics of the fuel determine the conversion technology selection. These include:

- Moisture content

- Ash characteristics

- Ash content

- Sulfur and nitrogen content

- Contaminants (chlorides, VOCs, heavy metals)

- Particle sizing and processing requirements

- Availability and transportation requirements

As you have just read, there is much more to biomass use and disposal than simply burning it for power.

-

Read: Fundamentals of Biogas

-Basic information:

- Biogas is a saturated, gaseous mixture of CH4 and CO2

- Contaminants often present include air, H2S, and NH3

- Solid and liquid residues remaining after anaerobic digestion are referred to as digestate

- Digestate can be used as biofertilizer

- Biogas can be used to generate power or upgraded to Renewable Natural Gas (RNG)

Biogas is readily upgraded to pure methane by removing CO2 and contaminants, whereas methanation requires intensive processing.

Upgrading biogas to RNG:

- Contaminants (air, H2S, siloxanes), moisture, and CO2 all need to be removed to upgrade biogas to RNG

- Technologies include:

- Pressure-swing adsorption

- Membrane separation

- Water/amine scrubbers

- Solid sorbents

Separating inert gasses:

- CO2 is the primary inert component of biogas that needs to be removed to facilitate RNG injection into pipeline

- Removal of N2 and O2 typically accomplished with PSA and noble- metal catalyzed redox, respectively

- Relative benefits and disadvantages of each inert gas separation technology can be discussed with Southern if desired

- Main technologies under consideration:

- Pressure swing adsorption (PSA) – cyclic adsorption via pressurization and depressurization in multiple vessels

- Membrane separation – selective permeation of unwanted constituents

- Water scrubbing – absorption of unwanted compounds based on relative solubilities in water

- Amine scrubbing – reaction of acid gases with amine solution in two-column process

Capturing hydrogen sulfide and siloxane:

- H2S Capture

- Primary focus given to solid scavengers (e.g., SulfaTreat, SulfurTrap, AxTrap)

- Liquid scavengers can be competitive with solids, but generally at higher sulfur levels

- Caustic scrubbers with regeneration can be competitive in some applications downstream of CO2 removal

- Sulfur quantities often too low for most “regenerable” technologies (e.g., liquid redox, biological, etc.)

- Siloxane Capture

- Organic silicon polymer compounds (aka siloxanes) mostly in LFG and WWTP biogas

- Similar to H2S, siloxanes captured via scavengers and regenerative media

- Deep chilling, as part of moisture removal, expected to remove portion of siloxanes

- Activated carbon polishing dominant for removal of trace amounts

Markets for biomass and co-products:

- Solid/liquid/gaseous biofuels

- Food, feed, and fiber

- Animal bedding

- Biochar

- Nutrients

- Energy production

-

Discuss: Applications at Your Plant

-Key takeaways:

- Bioenergy has broad applicability across almost every sector of the global economy

- Bioenergy is not a panacea, but has always and will always have a place in a sustainable energy mix

- Feedstock (the raw material) characteristics dictate selection of primary conversion technology, regardless of final product type

- Thermochemical conversion = “low moisture” feedstocks

- Biochemical/chemical conversion = “high moisture” feedstocks

- Biogas can be upgraded to pipeline quality or utilized directly

- Numerous markets for biomass and co-products, some more high value than others

Looking at your plant, what opportunities do you see for using biomass and biogas?

-

-

Wind and Solar Energy

-

Read: Wind and Wind Energy

-Wind energy will play a significant role in America’s energy transformation.

PepsiCo Goals:

- 100% Renewable Energy for World-wide Operations by 2030

- NetZero Emissions by 2040

The role of wind:

- 2021 total wind capacity: +120 GW, about 8.4% of total use

- Carbon-free by 2050 = 1000+GW, 44% of total use

- Totals = Solar + Wind + Storage + Other

Wind Energy Options:

- Power Purchase Agreements (PPAs)

- Renewable Energy Certificates (RECs)

- Onsite generation:

- Building DG-connected facilities

- Building behind the meter facilities

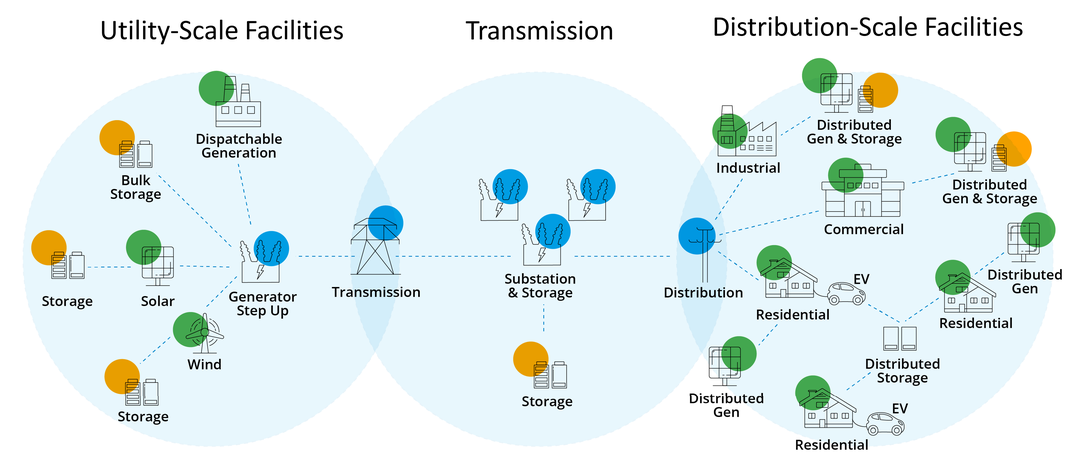

How wind fits into the energy mix:

-

Watch: How Wind Turbines Work

-In this video, explore how wind turbines convert wind into electricity, and the challenges of powering the world entirely with wind energy.

-

Read: Onshore and Offshore Wind Technology

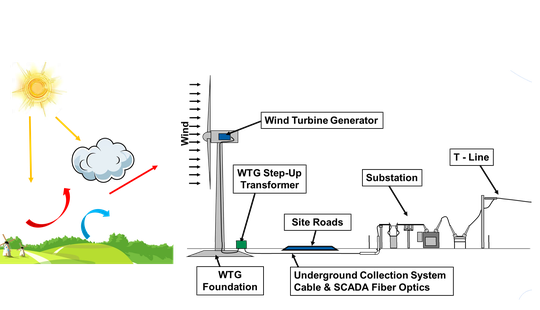

-Below are the components that go into the technology that turns wind into energy.

Onshore components:

As you can see above, there are multiple components to onshore wind energy generation. Not only the Wind Turbine Generator (WTG), but transformers, underground collection systems, a substation, and the wires to transport the power to the grid. Additional components include a meteorological tower to provide wind and environmental information and an operations building that serves as the center for meetings, some repairs, storage, etc.

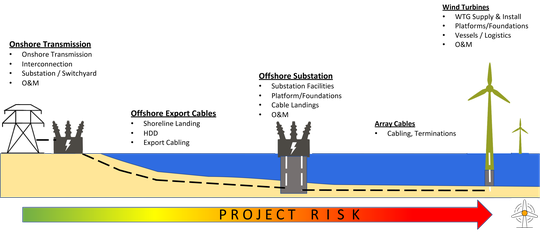

Offshore components:

The foundations of the offshore substation and the turbines may vary, but the basic components are the same. Because of the costs, floating foundations are being pushed. Other challenges include environmental, coastal operations, and the integration of the power transmission system.

-

Watch: How Solar Panels Work

-This video examines how solar panels convert solar energy to electrical energy. Do you think it's possible that the world will be reliant on solar energy eventually?

-

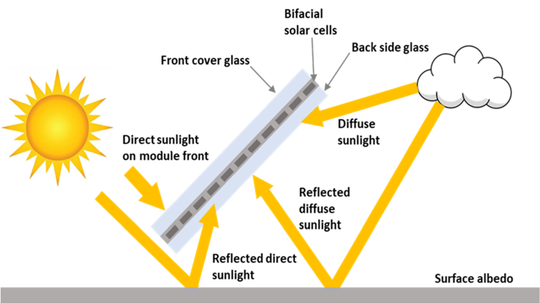

Read: Solar Technology Trends

-The field of solar technology continues to move forward. One trend is bifacial photovoltaic (PV) cells. These cells can absorb energy from both sides.

- Typical PV module bifaciality is 70-80%

- Only applicable for utility scale PV installations

- Bifacial gain is dependent on surface reflectivity (albedo)

- Typical 3-8% boost in annual energy vs. non-bifacial PV plants

The greater the albedo (reflection), the higher the backside performance will be on the PV module. Snow is a great surface for bifacial module performance.

Another trend is the movement to larger PV cells.

- Larger cells and modules allow for fewer modules needing to be deployed

- Not more efficient per given area, just more energy per module

- Additional trend of tighter cell packing in modules helps increase overall module output

-

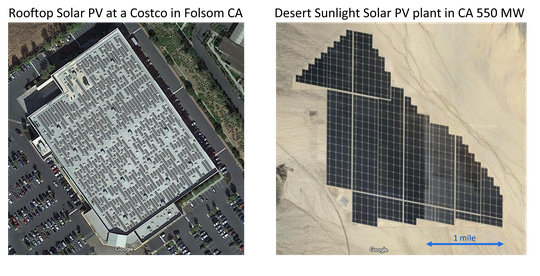

Read: Solar Energy Development

-Solar energy is being developed at different scales.

- Residential Scale (rooftop) Solar PV

- Delivers energy directly to the home level

- Commercial Scale Solar PV

- Delivers energy directly to the business offsetting energy needs

- Utility Scale Solar PV

- Lowest cost of delivered solar energy

Here are some examples:

-

Discuss: Solar and PepsiCo

-Key takeaways:

- Solar energy is free.

- Solar energy systems are setups that are meant to harness sunlight and convert it into usable electricity for homes and businesses.

- Solar power is safe and completely renewable. It is also a clean energy source that emits no carbon. It is considered a key technology in combating climate change.

- Solar power is the only renewable energy source that’s practical to use in most homes and businesses, bringing the electricity generation directly to where the need (load) is located.

- Solar power is readily adaptable to battery energy storage systems for reliable energy delivery to homes, businesses, and the electric grid.

Benefits to PepsiCo:

- Solar power is becoming the most common way to meet sustainability and CO2 emission reduction goals.

- Commercial scale solar PV systems could readily be installed at numerous PepsiCo bottling and distribution locations around the country.

- Investing in solar power now can be viewed as a hedge against future energy price increases (energy is not getting any cheaper).

- Solar power paired with storage (batteries) is even better!

How do you think solar energy would work in your location? Why?

-

-

Battery Energy Storage

-

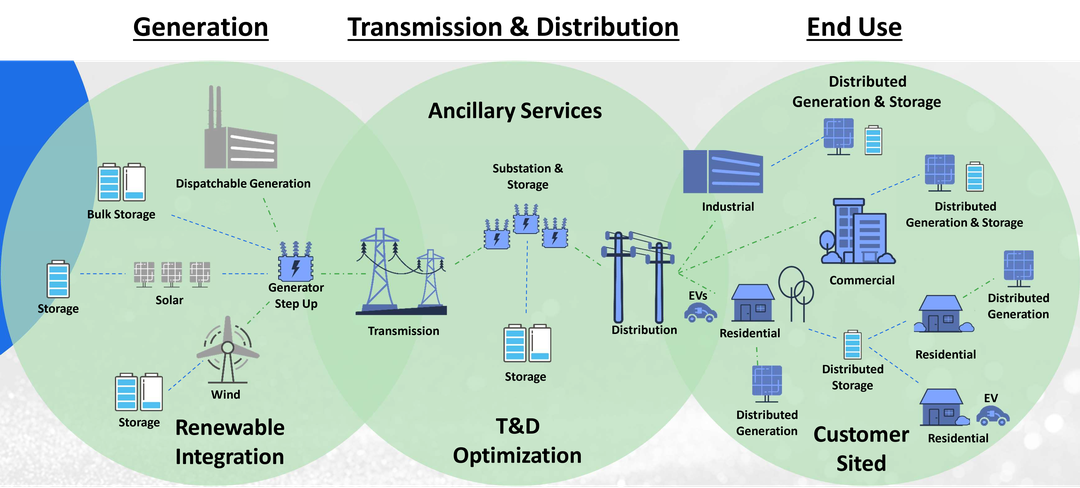

Read: Energy Storage Definitions and Technologies

-Now that you've learned about various ways to generate energy, we look at storing the energy. We can't use all the energy generated by wind, solar, or other methods immediately, so there are ways to store the energy until it is needed.

Definition of Energy Storage and Battery Energy Storage Systems

- Energy storage system (ESS) refers to the device that converts electrical energy from power systems into a form that can be stored for converting back to electrical energy when needed.

- Battery energy storage system (BESS) is a type of ESS. It is an electrochemical device that charges (or collects energy) from the grid or a distributed energy source (like solar, wind) and then discharges that energy at a later time to provide electricity or other grid services when needed.

Energy storage systems are a time machine for electricity – they move energy from now to later.

Energy Storage Technologies

- Thermal - molten salt, crushed rock, molten aluminum, liquid air energy, pumped heat

- Mechanical - gravity storage, pumped hydropower, compressed air, flywheel

- Hybrid - thermochemical pumped heat, power to X (P2X)

- Electrochemical - Li-Ion, flow, lead acid, sodium based, metallic-based

- Chemical - hydrogen, ammonia, methanol

- Electromagnetic - superconducting magnetic energy, super/ultra capacitors

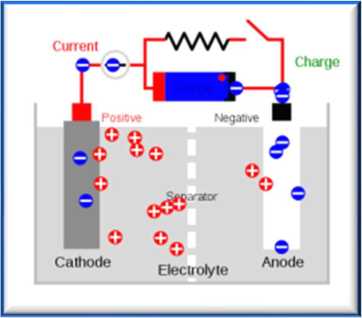

Electrochemical Energy

- Batteries are electrochemical cells that convert chemical energy into electrical energy

- Electrochemical oxidation-reduction (redox) reactions occurs at each of two electrodes

- The positive electrode (cathode)

- The negative electrode (anode)

- Separated by the electrolyte

- The resulting potential, i.e. voltage, is determined by the material composition of the electrodes and the redox reactions that occur

- Primary batteries use up their chemicals and are replaced

- Secondary batteries are reversible and are charged and discharged

Desirable Attributes of Lithium Ion Batteries

- Excellent Cycle Life: Lithium ion technologies have superior cycling ability to other battery technologies such as lead acid.

- Fast Response Time: Lithium ion technologies have a fast response time which is typically less than 100 milliseconds.

- High Round Trip Efficiency: Lithium ion energy conversion is efficient and has around 94 percent round trip efficiency (DC-DC).

- Versatility: Lithium ion solutions can provide many relevant operating functions.

- Commercial Availability: There are many top-tier Lithium ion cell suppliers and many power conversion system suppliers

- Energy Density: Lithium ion solutions have a high energy density to meet space constraints.

Lithium ion is currently the battery of choice, but others are maturing.

-

Watch: How Batteries Work

-This video provides the basics about batteries, including why their power diminishes and how they store the energy for later use.

-

Read: Energy Storage Trends and Drivers

-Below are the trends and drivers relating to energy storage. Today's systems aren't perfect, but are continuously being improved upon.

Global Storage Growth Trend

- Current stationary and transportation energy storage market is sized at 800 GWh

- By 2030, these markets are expected to add 2.5-4 TWh annually

- This is a 3-5X increase in storage capacity

Drivers for Storage Growth

- Continued lower prices and expanded markets and applications

- Market rules established and improved for monetization of benefits

- BESS equipment industry consolidation and maturation

- Increased intermittent and periodic renewable energy

- Customer desire for more control over energy costs

- Customer commitment for sustainability and carbon emission reductions

- Customer desire for reliability and resiliency

-

Read: Batteries and the Grid

-Storage imparts flexibility, reliability, and resiliency to the power grid—and to electricity customers.

The value of a use case and/or application is location specific, and depends on policy, regulation, operations, infrastructure age, and other factors.

-

Discuss: Benefits for PepsiCo

-How Storage Can Help Control Energy Costs

- most electric bills consists of:

- Consumption charges - how much energy is used

- Demand charges - increased rates based on high demand

- Can contain time of use rates - increased rates during peak usage times

- Storage can provide:

- Peak rates shaving (use the stored energy during peak usage times to reduce costs)

- Time of use price shifting (use the stored energy during times where the electric costs are increased)

Power Quality, Capacity, and Resiliency

- Reduced Downtime — An energy storage system can ensure critical operations are maintained during a grid outage.

- Power Quality Management — For manufacturing and services that require high quality power, a battery storage system can help reduce or eliminate frequency changes, voltage sag, and power factor issues.

- Capacity — Energy storage can provide support for increased electric capacity required during periods of grid constraints for electrification projects like conversion of fleet vehicles.

What benefits do you see in using energy storage for your plant? What would need to change to implement a storage solution?

-

-

Renewable Fuels of the Future

-

Read: Solid Biofuels

-Biofuels cannot be used in their original form. Think of putting an entire tree in a fireplace. The tree won't fit in the fireplace intact and the wood needs to be dried out (seasoned) to burn better.

Solid Biofuels Overview

- Biomass/waste processed into a densified geometry to facilitate transport/conversion

- Processing often includes:

- Size reduction

- Densification

- Moisture removal

- Additional thermal treatments:

- Torrefaction

- Steam explosion

- Hydrothermal carbonization

More about Thermal Treatment:

- Improving safety characteristics

- Off-gassing

- Dust formation

- Pellet pile self-heating and spontaneous combustion

- Enhancing combustion properties

- Grindability

- Water resistance

- Increasing co-firing capabilities while minimizing capital costs improvements needed

- Promoting durability and transportability

- Lower microbial growth

- Impact resistance and compressive strength

Solid Biofuel Key Take-Aways

- “White” pellet processing involves size reduction, densification, and drying to yield modestly priced product

- Additional thermal treatments improve on safety, combustion, and durability characteristics

- Some thermal treatments enhance certain characteristics more than others, but come at significant cost

- Economic justification unclear

- Opportunities for co-firing and repowering must be closely investigated

- Waste densification represents new and emerging market

- Organic components must be suitably stabilized

- Minimize odor and other longevity issues

-

Read: Liquid/Gaseous Biofuels

-Biofuel technologies continue to improve over time. Below is a progression of various technologies, and where they are headed for the future.

Progression of Liquid/Gaseous Biofuel Technologies

- 1st Generation Biofuels: Commercial

- Feedstocks: Food crops

- Minimal greenhouse gas (GHG) savings

- Currently commercially produced, highly dependent on subsidies

- Potential threat to food supplies and biodiversity

- Pathways: Fermentation and transesterification

- Fuels: Ethanol and biodiesel

- 2nd Generation Biofuels: Near-term

- Feedstocks: Energy crops, residues, wastes, forestry biomass

- Significant GHG savings

- Currently in demonstration/scale-up

- Pathways: Biochemical, thermochemical, etc.

- Fuels: Ethanol, butanol, dimethyl ether, renewable natural gas (RNG), advanced hydrocarbon biofuels (green gasoline/jet fuel/diesel)

- 3rd Generation Biofuels

- Feedstocks: Algae, Carbon Dioxide, Water, Ag Residues

- Greatest GHG savings

- Currently in research & development

- Major Pathways:

- Hydrothermal Liquefaction

- Lipid Extraction and Upgrading

- Gas Fermentation

- Renewable/Photosynthetic Electrolysis

- Enzymatic/Other Photosynthesis

- Fuels: Alcohols, hydrogen, advanced hydrocarbon biofuels

Sugar Extraction and Conversion

- Starch- and sugar-rich biomass feedstocks (corn, sugar, sorghum) are most common types used for biofuel production

- Sugars extracted through rudimentary milling/cooking

- Fermentation of sugars to produce simple alcohols such as ethanol

- Lignin content of cellulosic feedstocks (agricultural residues, grasses, wood) hinder direct extraction of sugars

- Pretreatment followed by enzymatic hydrolysis required to yield fermentable sugars

- Sugars subjected to traditional fermentation or undergo other catalytic/ biological conversion to yield other hydrocarbons (diesel/gasoline blendstocks)

Oil Extraction and Conversion

- Lipid-bearing feedstocks (soy, tallow, jatropha) are used for the extraction of oils that can be converted into several different types of biofuels

- Oil can be mechanically extracted (using expellers and presses) and/or chemically extracted (solvents)

- Biodiesel is produced from extracted oils via transesterification

- Renewable diesel blendstocks can be produced through isomerization and hydrotreating to upgrade oils to “drop-in” biofuels

- Algae is an emerging feedstock for production of advanced biofuels using variety of conversion processes that are still in development

Gasification Fundamentals

- Conversion of carbonaceous material in reducing atm, aka partial oxidation

- Product: Synthesis gas (syngas) composed of CO and H2

- Oxidants: Air, oxygen, steam

- Byproducts: biochar, ash, slag

- Operating temperatures generally in the 1,200°F to 2,900°F range

- Types of gasifiers:

- Fixed/moving bed

- Fluidized bed

- Entrained flow

- Indirectly heated

- Advanced (catalytic, plasma, etc.)

Pyrolysis Fundamentals

- Endothermic, thermal decomposition of carbonaceous material occurs in atmosphere that is devoid of an oxidant

- Typically occurs at lower temperatures and equivalence ratios than gasification

- Results in the production of syngas, condensable vapors, and char

- Condensable vapors recovered/upgraded to produce biofuel product

- Pyrolysis gas combusted for process heat or purified to produce hydrogen for upgrading fuel product

- Char can be recovered as soil amendment product or combusted for process heat

Biofuel Refining

- Each combination of feedstock, conversion, and biofuel product has set of refining requirements

- These “unit operations” require other consumables incl. catalysts, solvents, reagents, parasitic power, filtration, etc.

- Major classes of refining processes include:

- Acid gas conversion/removal

- Contaminant conv./removal

- Hydrocarbon synthesis

- Hydrotreating

- Product separation/recovery

Fuel Specifications

- A mixture of liquid chemical components is not considered a “fuel” until it meets a specification

- American Society for Testing and Materials (ASTM) is the primary specification authority for liquid fuels; European markets have equivalent

- The following ASTM specifications are relevant to the biofuels discussed in this presentation

BIOFUEL

ASTM SPECIFICATION(S)

E10/E15 Ethanol

D4814 & D4806

E85 Ethanol

D5798 & D4806

Jet

D7566 & D1655

Diesel

D975

Gasoline

D4814

Renewable Natural Gas (RNG) Overview

- RNG defined as methane-rich gaseous biofuel that can be cleaned to pipeline quality standards and blended with fossil-derived gas

- Can be derived from variety of sources:

- Landfills

- Wastewater treatment plants (WWTPs)

- Anaerobic digestion (manure, organic waste)

- Woody biomass

- Energy crops

Anaerobic Digestion (AD) Fundamentals

- AD involves biodegradation of organic materials by microorganisms in the absence of oxygen

- Complex reactions involving bacteria and archaea

- Biogas is produced and consists primarily of methane and carbon dioxide

Manure to RNG Considerations

- Manure from large confined animal feeding operations is substantial

- AD is effective for odor/nutrient management as well as energy

- Frequently used for:

- Dairy cows

- Swine

- Poultry

- Clustering can be effective for on-farm AD with central biogas cleaning/upgrading

- Favorable economies of scale

- Overcome challenges with permitting, interconnection cost, environmental compliance

- Safety concerns with biogas piping (i.e., H S)

- Co-digestion of manure / food waste offers significant promise to increase biogas yields

-

Watch: Hydrogen

-You’ve may (or may not) have heard of green hydrogen, but have you also heard of blue or grey hydrogen? This video provides an overview of hydrogen production pathways and the colors often used to describe them.

-

Watch: Top 10 Energy Sources of the Future

-This video covers 10 of the most promising energy sources that may be responsible for decreasing our reliance on fossil fuels.

-

Discuss: Best Energy Options for Your Site

-You have learned about available and future energy options, such as biomass, biogas, wind, solar, carbon credits, and technologies to store energy until it is needed. You also have seen some possible energy sources for the future.

Given that PepsiCo has ambitious pep+ goals, what do you believe is the best current or future energy option for your site, and why? What barriers do you see with implementation?

-

-

Capstone Call

-

Attend: Capstone Call

-This 30 minute call will conclude the course. The purpose of the call is to:

- Assess and review completion

- Check for understanding

- Answer any questions that people may have

-

• Recommended for: ReCon Leader, ReCon contact person, Maintenance Managers, Process Improvement Engineers, Regional Leaders, and Project Engineers.

• Pre-requisites to take this course: There are no pre-requisites for this course.

For 2022, this course will be offered starting August 8, 2022. Register here at least a week prior to the start of the course. Please keep in mind your schedule and time commitment required prior to registration.