Closed Enrollment

Published Course

ReCon Program Basics

ReCon Program Basics

Course Created in Partnership with:

About this Course

ReCon Program Basics is an introductory course targeted to ReCon leaders and site leaders. With the increasing environmental challenges world wide, the bar is being raised for all of us. ReCon is an important step in our journey to deliver strong financial returns in a way that is sensitive to the needs of the world. We can future proof PepsiCo by aligning good-for-business and good-for-planet and society. We can be a role model for leadership in sustainability. ReCon is the way forward and everyone has a role to play in the initiative. If we can effectively drive our ReCon strategy, we will demonstrate in our facilities and in our communities that we are part of the solution in reversing the effects of climate change, water scarcity, and waste landfilling three of the defining issues of our time.

Through this course you will learn all about ReCon and specifically how we will address the resource conservation opportunity - to help minimize PepsiCo's environmental footprint.

How to Enroll?

Enrollment in the course is easy. Once you enroll, you will receive course details and login information 1 week before the course starts.

- If you have taken a course with us previously, simply click on Enroll Now for the date you want to take the course.

- If you are a new student to ReCon, complete the registration form using the link at the bottom of this page called ReCon Training Registration Form.

Course Features

-

100% Online

Accessible from any device.

-

Self Directed

Learn with a cohort but when it fits in your schedule.

-

On-demand Video

Interactive video lessons.

-

Beginner Level

No prior experience required.

-

PepsiCo Internal Expertise

Brought to you by Global Sustainability Operations

What people are saying about ReCon Program Basics

What You Will Learn

- PepsiCo’s sustainability vision and plan to move forward.

- Learn the PepsiCo resource reduction commitments

- How ReCon must be integrated into the business

- Learn about some ReCon tools that can be leveraged immediately

- Evaluate if your plant is well structured to tackle the challenge

- Explore what some other locations are doing

Course Overview

10 Lessons

50 Activities

9 Discussions

3 Live Events

Welcome

-

Welcome to ReCon Program Basics

-

Attend: Kickoff Call

-

Join this kickoff call to learn about:

- Introduction to the CorpU platform and how it works

- Overview of this sprint and how it fits into the stages long term

- Open-ended poll or discussion: What's the most recent thing your plant has done for resource conservation?

-

Watch: Importance of ReCon

-Watch as Roberta Barbieri, the Sustainability Vice-President, talks about why ReCon (short for Resource Conservation) is so important to PepsiCo.

-

Profile: Create Your Profile

-Please take a few minutes to upload your picture and bio so everyone can start getting to know you. Make sure you include your current role, plant, and any hobbies. It's time to get creative.

-

Discuss: Meet Your Cohort

-

It's time to meet your colleagues on this journey so take a few minutes to join them in a brief discussion.

In this, the first of many posts, please let us know the work you are currently involved in. Include one goal you would like to accomplish as an outcome of this course.

Get to know your colleagues by scanning through their profiles and their posts. Maybe someone has something in common with you or has experience in an area that interests you. Use the discussion to let them and others know.

-

ReCon Program Basics

-

ReCon and PepsiCo's Vision

-

Watch: PepsiCo's ReCon Vision and Goals for Sustainability

-Watch as Anna Palazij, VP Reporting & Strategic Investments, tells you about the current ReCon goals for PepsiCo. Think about how these goals and vision impact PepsiCo's financials in preparation for a discussion later. Note since the filming of this video the ReCon agenda and Global Sustainable Operations team has moved under Roberta Barbieri, VP Climate & Water - Global Sustainability Office, and Johan Delmoitie, Director of Global Sustainable Operations.

-

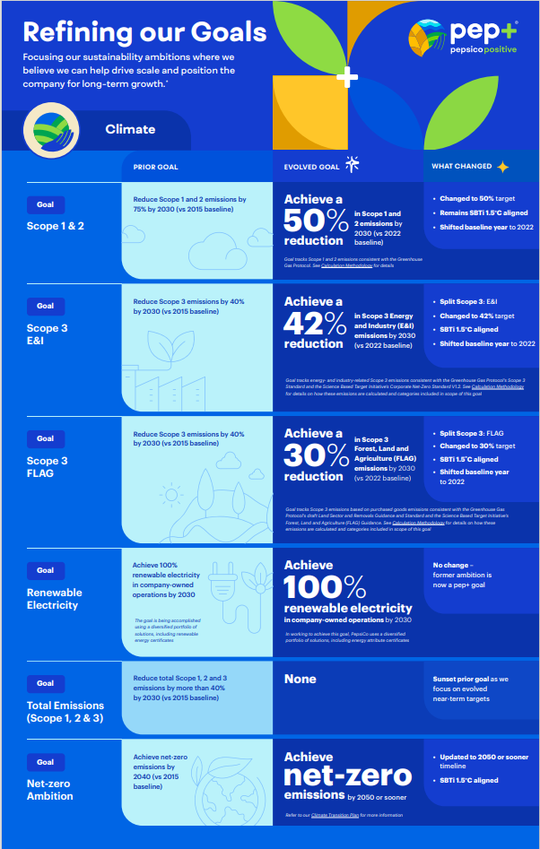

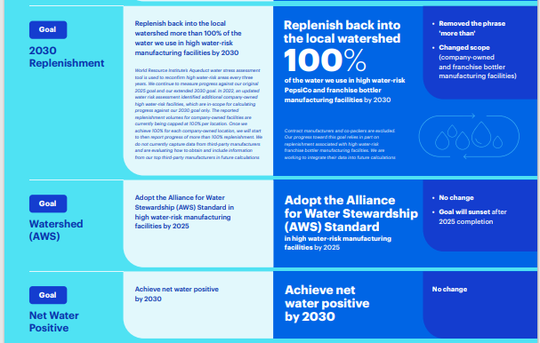

Read: PepsiCo's Goals

-On May 22, 2025, PepsiCo announced refined climate, packaging, agriculture, and water goals. This ESG Summary reflects PepsiCo’s 2023 progress against our previous pep+ goals.

.

As you can see, we still have a way to go in some areas of resource conservation and all the goals need your help on this critical journey to conserve our planet's resources.

Want to read more? Check out the ESG Summary on PepsiCo's website.

-

Reflect: ReCon, Customers, and Consumers

-In the box below, capture your thoughts about how ReCon benefits PepsiCo's customers and consumers. Be as specific as you can to make PepsiCo's vision meaningful to you.

-

Discuss: ReCon and Business

-In this cohort discussion activity, let's talk about the connections between sustainability and PepsiCo's financial performance.

- How does resource conservation make or save money for PepsiCo?

Once you've shared your opinions, review those of your colleagues and react with likes or responses to at least two of them. Be sure to check back to see what your colleagues are saying.

-

-

What is ReCon?

-

Read: ReCon History and Overview

-So, what exactly is ReCon and where did it come from? ReCon is a global program that supports sustainability, resource conservation, and productivity. It tells us where we are, where we should be, and how to get where we could be in the areas of energy, water, and waste.

ReCon was originally developed for PepsiCo International but has evolved into a global resource conservation tool for PepsiCo. It was designed based on the standard Best Practice structure used by PepsiCo:

- Objectives: Optimize water and energy usage, minimize waste, and minimize the impact on local communities.

- Principles: Develop globally, implement locally, enable accurate and calibrated performance tracking, provide process tools and project-based solutions, link to the PepsiCo Sustainability initiative, and incorporate rewards and recognition.

- Processes: Standardize scorekeeping with globally benchmarkable metrics using site-level scorecards, use operating best practices, and use project-based technical solutions.

- Tools: Use a standardized scorecard, ReCon Maturity Model, Best Practices listing, and online resources/information repository to share information.

- Implementation: Identify, train, and develop regional captains and local point people, facilitate the exchange of knowledge and best practice, and expand implementation across the PepsiCo system.

-

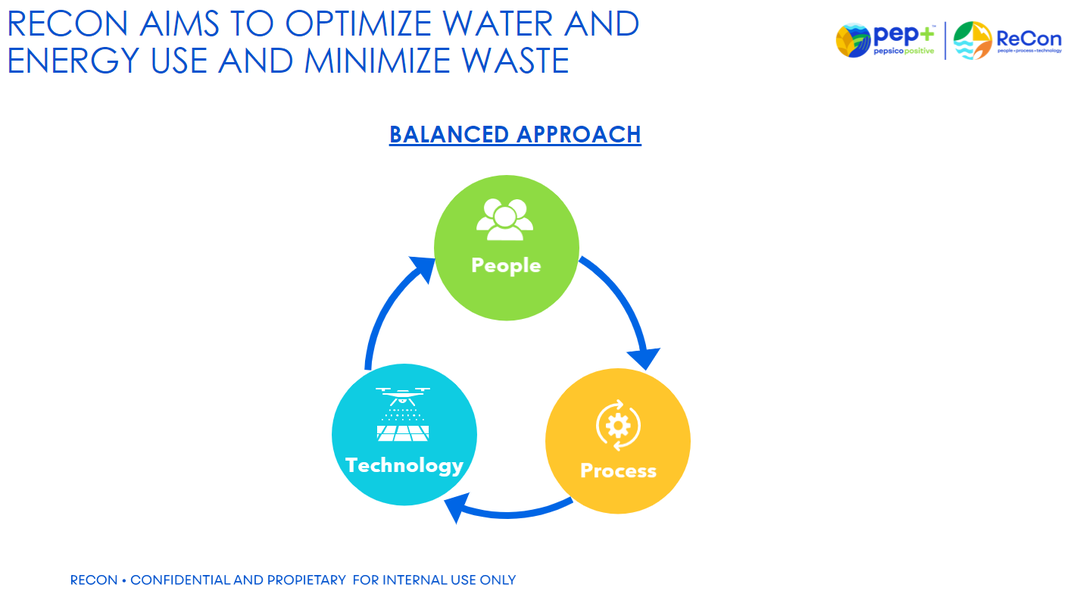

Read: ReCon and pep+

-Today in PepsiCo, ReCon helps deliver pep+ climate and water goals while generating productivity for the business.

Our ReCon program provides a set of systems, tools and best practices to maximize our operational water and energy use efficiencies and minimize waste.

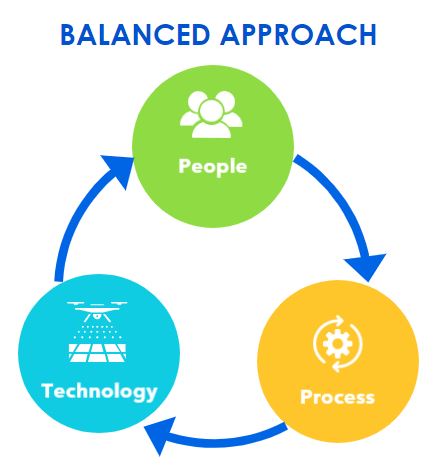

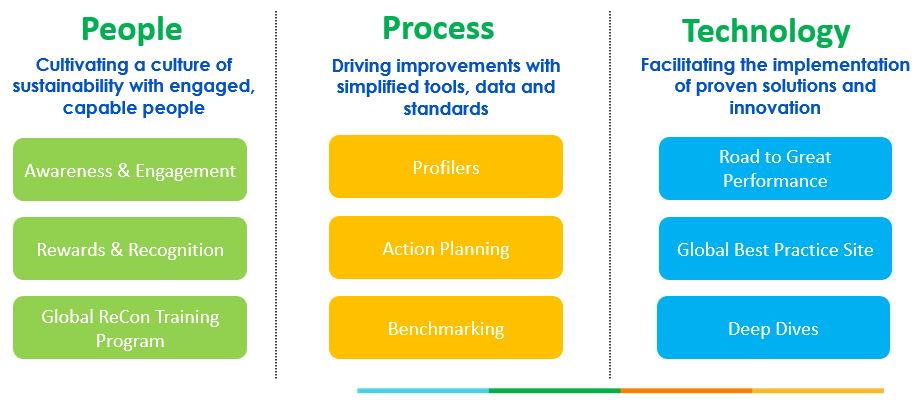

This is done through a balanced approach of people, process and technology.

It is important our programs are comprehensive and consider all three areas (people, process and technology) in order to be sustained and deliver the best performance.

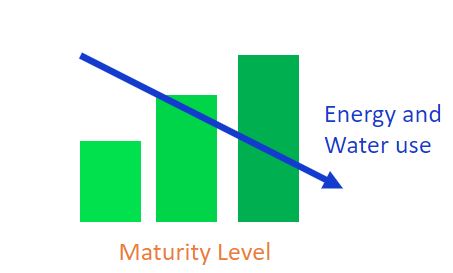

A world-class ReCon maturity correlates with productivity savings and leads to world-class performance.

-

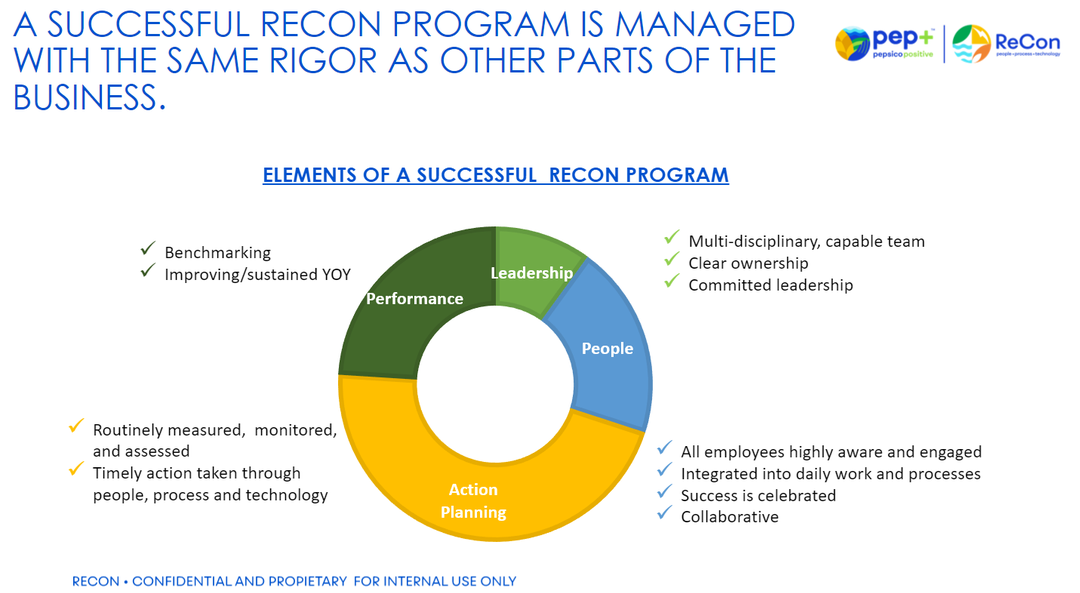

Read: Building a Successful ReCon Program

-Before you can build a successful, mature ReCon program, you need to know what success looks like.

If areas of your ReCon program(s) have opportunities or are missing, that is ok. This is what ReCon is all about! There are systems and tools available to develop and sustain world class ReCon programs.

These programs are outlined below and we will go into more detail on most areas throughout the course.

-

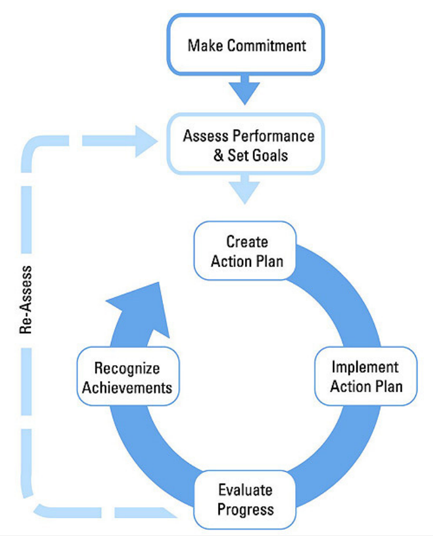

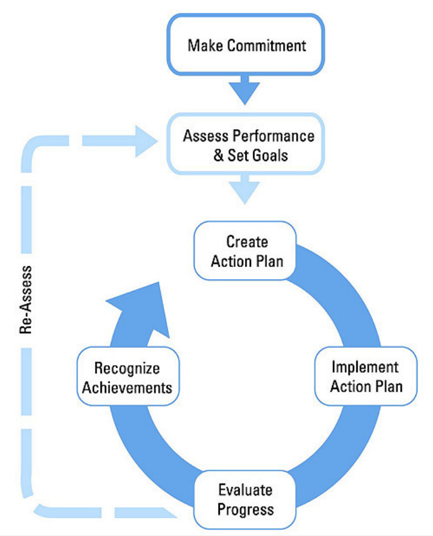

Read: Basic Recipe for Success

-The Basic Recipe for success gives us the process of how we can implement our ReCon programs.

The basic recipe for success has 4 ingredients:

- Making a Commitment

- Assessing Performance and Setting Goals

- Creating and execution of action plans through people, processes, and technology

- Driving continual improvement and sustainment through awareness, recognition and re-assessing performance

We'll review each of the ingredients in more depth tomorrow and how the elements of the ReCon program mix with each ingredient.

-

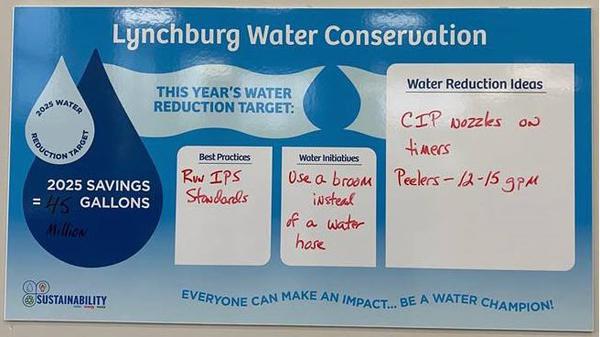

Discuss: Water Conservation Methods

-

Let’s look at one resource – water. We use water in many ways, and yet, we don’t want to harm communities by putting pressure on their water supplies.

- Where is water used in your plant and how can it be conserved using people, processes, and technology?

Once you have made a post, build on others' ideas by responding with a comment or two.

-

-

Basic Recipe for ReCon

-

Read: Commitment to ReCon

-The first step in the recipe for success is gaining commitment. It is critical for all areas of the business to be committed to ReCon and sustainability.

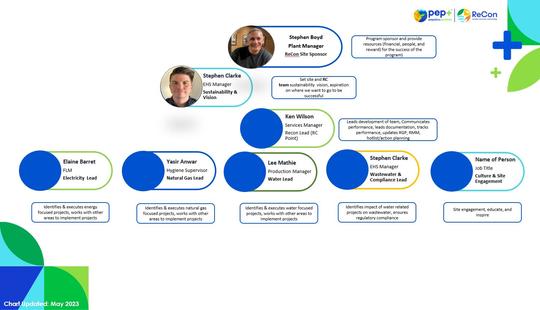

In our sites, this means that the leadership team commits to ReCon and everyone is accountable for meeting goals.

A successful ReCon program has a sponsor, an owner and a multi-disciplinary team with clear roles and responsibilities. It is key to discuss and document roles and responsibilities with team members so everyone is clear. In addition, communicate out to the site who is on the team so all employees know who can support them when it comes to ReCon.

The document below provides an example of a structure for a ReCon team and can be used to document your team. Do not worry if you do not have as many people on your team vs. shown on the chart. You should strive to have a team that is appropriate and reflective of your site - try to have representation from all departments and shifts so you have champions embedded throughout the site!

-

Read: Assessing Performance

-Assessing performance and setting goals is the second part of the basic recipe. It includes:

- Local goals and scorecard — Measuring and monitoring trends and taking action

- Game plans with tactics that have owners and timelines

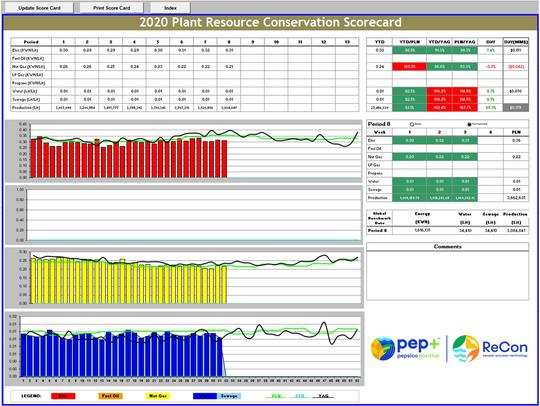

This image gives you an idea of what a plant scorecard looks like:

Download the scorecard image to see more detail and use at your site if you need a template.

-

Read: Driving Sustained Performance

-Drive sustained performance through Teams, Processes, Technology, and Innovation

- Organize and build teams – Train / Motivate / Recognize

- Leverage existing processes – SOPs, Dashboards, Audits, Lean Six Sigma, Continuous Improvement

- Find and develop technology that improves efficiency

- Innovation drives productivity – foster, encourage, and share best practices

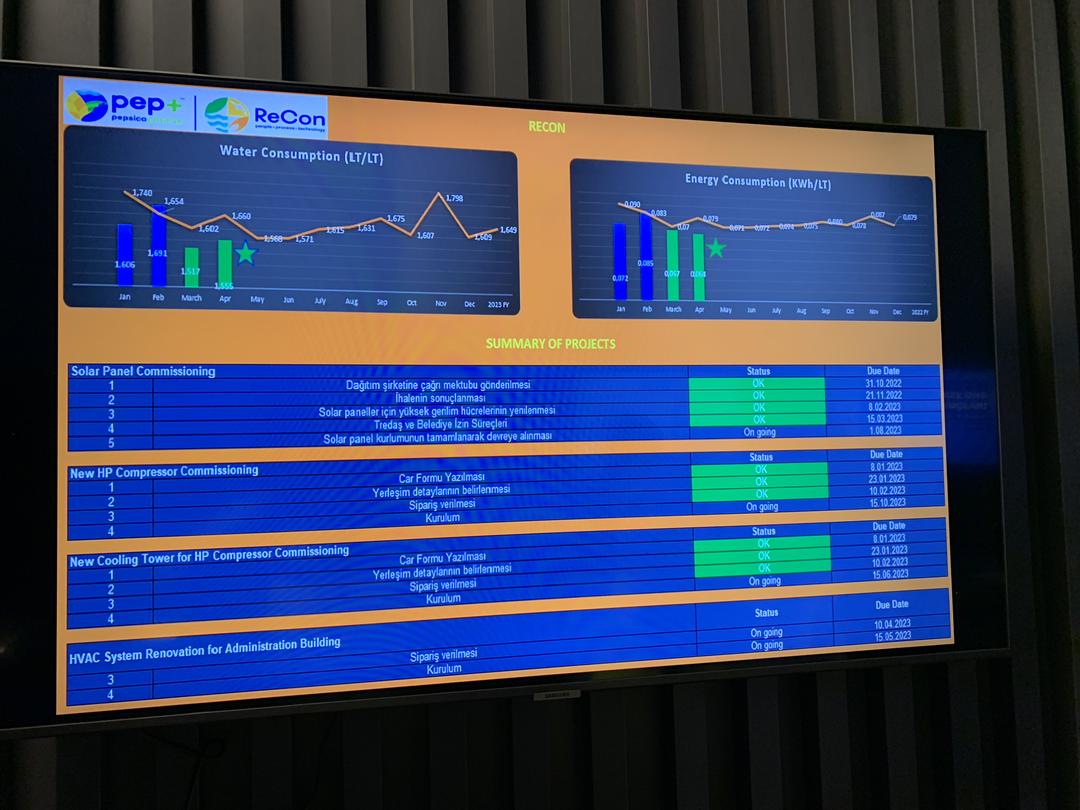

Below are a few examples from our sites showing how ReCon is communicated to the rest of the site.

-

Watch: Awareness, Communication, and Engagement

-Watch this short video about how to increase awareness and engagement about ReCon.

Download the newly created ReCon Frontline Engagement Playbook and templates. The material will help you with setting up a ReCon team if you are in the process of creating your team and kickstart your ReCon Employee Engagement program on site.

-

Read: How PepsiCo Achieves Productivity

-You read yesterday about the qualities needed to build a successful ReCon program. Let's take that one step further and build those qualities using the same processes as other functions within PepsiCo.

Productivity requires process, strategy, execution, and endless determination

. Do you have what it takes?

. Do you have what it takes?- Set a big challenge - little goals produce little results

- Create a team - every site needs experts with enthusiasm

- Budget - we're all driven by the numbers

- Scorecard - the budget doesn't show true performance

- Audit / deep dive - demand success and help to achieve it

- Innovate - you know your own business best, always validate your ideas with the correct stakeholders (quality, safety, etc.)

- Execute - the best laid plans...are still just plans

- Communicate results - share the stories and rewards of success

-

Reflect: Observation

-

As you walk through your plant over the next 24 hours, jot down what you notice your plant is doing for ReCon.

- Do you see any ReCon posters/other communications?

- Have you seen emails about ReCon?

- Are water and energy KPIs visible (i.e. up to date water/energy scorecards displayed for all employees to see)?

- What else do you see? If you cannot find information on display, take it as an opportunity to improve your ReCon engagement and awareness program.

-

Watch: Employee Engagement

-Watch a leader at one of our plants discuss why awareness and engagement is important to performance.

-

Discuss: What can you do for employee engagement?

-Let's use this discussion forum to share ideas across the company. Respond to the question below and then react to others' ideas with likes or responses that build on the ideas.

- How will you involve all employees in Resource Conservation in your plant, making sure that they are engaged and know the importance of ReCon?

-

Complete: Check for Understanding

-

-

-

Performance Tracking / Score Cards

-

Read: Basic Recipe Review

-Here's a quick review of the recipe for success.

As we begin looking into data collection, keep in mind the 4 ingredients for success:

- Making a Commitment

- Assessing Performance and Setting Goals

- Creating and execution of action plans through people, processes, and technology

- Driving continual improvement and sustainment through awareness, recognition and re-assessing performance

This section of the training is focused on assessing performance and setting goals.

-

Read: Robust Data Collection

-Below are the characteristics of a robust data collection.

Keep these in mind as you gather data for your Scorecard and review your site's maturity. (You will learn more about these as part of this course.)

- Relevance: Ensure the data appropriately reflects the data for the company and serves the decision-making needs of users – both internal and external to the company.

- Completeness: Account for and report all material data within the chosen boundary.

- Consistency: Use consistent methodologies to allow for meaningful comparisons of data elements over time.

- Transparency: Disclose any relevant assumptions and make appropriate references to the accounting and calculation methodologies and data sources used.

- Accuracy: Achieve sufficient accuracy to enable users to make decisions with reasonable assurance regarding the integrity of the reported information.

-

Watch: Measurement and Timely Action

-This video reviews what and when to measure and how to take timely action.

-

Discuss: Frequent Measurement

-In the video you just watched, we recommended timely, readily accessible measurements. The best practice in this area is to incorporate ReCon index review in daily production meetings.

- How will you overcome any barriers that you see to frequent measurement and review?

Once again share your thoughts, and then take time to respond to others. We can all use fresh ideas about how to overcome barriers that we see.

-

Attend: Live Event

-

Agenda:

- Check in on progress

- Answer any questions

- Review highlights of the discussions

- Quick wins

-

ReCon Program Basics - Execute and Sustain

-

Reading Utility Bills

-

Read: Why Utility Bills Matter

-The short answer to why utility bills matter: Data that leads to insights and action.

Utility bills are a window into usage and charges. Knowing how to read your plant's bills—and tracking usage and costs over time—can give you an indicator of progress. It can show you and leadership how you are making progress with your ReCon program, which brings you closer to impacting the overall sustainability goals covered earlier in this course.

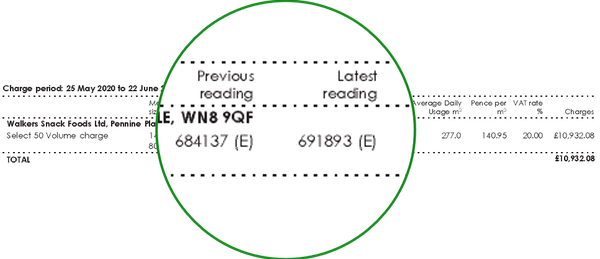

Below is a sample section of a water bill. Notice the (E) next to the meter readings. That means the reading is an "Estimate."

Tip: Check your bills against the meters whenever possible to ensure accuracy. Utility companies may estimate usage and it can vary widely from the plant's actual usage.

-

Read: Fixed and Variable Charges

-Utility bills have one thing in common whether they are for water, energy, or waste: Fixed and variable charges. Different companies may use different terminology, but it's important to understand what part of the total charge is "fixed" and what amount(s) is based on usage, i.e. "variable."

Fixed charges may be called a customer charge, daily charge, service charge, etc. These charges are normally for bringing the service to the plant and cover things like the meter reading.

Variable charges include the amount of water, energy etc. actually used, as well as taxes and other fees. The labels for the charges can vary based on the type of bill, the company providing the utility, and the location of the plant.

Important: At least yearly, meet with the utility company to go over billing.

- Is this the best pricing?

- What suggestions do they have for water/energy/waste conservation?

-

Watch: Reading Utility Bills

-Watch this video on how to read utility bills.

-

Read: Sample Utility Bills

-Download and review these sample utility bills. Identify how they compare with your personal utility bills and prepare for a discussion.

-

Discuss: Utility Bills

-Thinking about personal utility bills and those that we just reviewed for one of our plants, let's discuss what might be different.

- How are the utility bill examples from a plant different from your personal utility bills? Any surprises?

-

-

Your Plant's ReCon Program Status

-

Activity: ReCon Maturity Document and Plant Visit

-Do you recall the elements of a successful, world class ReCon program?

You may be wondering how can we determine where your site is at in this journey.

Fortunately, ReCon has a tool for that in the ReCon Maturity Assessment.

The ReCon Maturity Assessment is a tool used annually to assess plant maturity across four (4) categories – leadership, process, action planning and performance (look familiar?).

This assessment provides insight on a plant’s program status and its strengths and opportunities. In turn, the results provide direction on how to improve local programs and support the development of the improvement plan. Additionally, This assessment provides a tool to compare sites globally in a standardized way and helps understand universal gaps and needs for future development of solutions.

With the link you can download more information on the ReCon Maturity Assessment including the assessment itself, helpful templates for your program and additional guidance.

Familiarize yourself with the assessment and locate your plant's latest ReCon Maturity Assessment results. Review the results and ask questions to fellow ReCon team members as needed. Take a walk through your plant and compare what you see with the assessment.

-

Discuss: Plant Maturity

-Share the results of your plant maturity review and visit with your colleagues.

To get started, consider questions like: What is the maturity level of your plant? Are there obvious issues to be tackled now? Are problems fixed as they occur? Is there planning for sustainable performance? Does the assessment reflect what you saw on your visit?

If taking pictures is allowed in your location (ask your manager or the plant manager if you aren't sure), take and upload some pictures of communications or posters you found on your visit.

-

Reflect: Key Goal

-Reducing greenhouse gas emissions is a key goal of pep+ positive value chain pillar climate agenda and ReCon. Using what you saw during your plant visit and what you've learned so far in the course, reflect on how you can reduce greenhouse gas emissions in your plant.

Jot down your thoughts in the box below. You can return to this any time by using the "Backpack" icon at the top right of the screen.

-

-

Hotlist, Action Plan, Execute, and Sustain

-

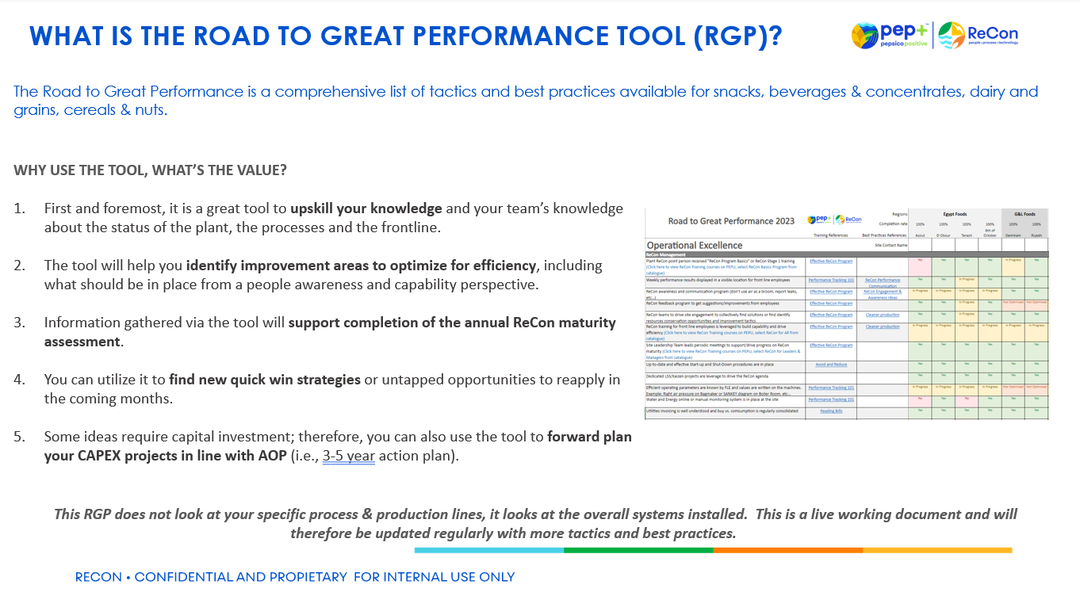

Read: Road to Great Performance / Best Practice Tool

-

Explore the Road to Great Performance tool using the link and see how many ReCon tactics your plant has adopted. Can you identify a few quick wins, i.e. tactics that could rapidly be implemented with relatively low effort that could help you drive the local ReCon agenda?

Click on the link below to access the tool. Select the file that represents your products (i.e. snacks, beverages, dairy or cereals/nuts grains)

Road to Great Performance Tool

Please add this link in your browser bookmarks as you might need to access this again in the future. The document is a live tool that stores information for all of our sites. It is regularly updated with new information, tactics and best practices. Your site should review it atleast once a year to ensure you are making the most of the information available.

Take a few minutes to also explore the Global Best Practices tool.

Click on the link below to access the

This platform is where the approved and globally replicable Best Practices are stored. You will find not only ReCon Best Practices but also several other types of best practices that will positively impact plant performance. It includes valuable information about quality, safety, maintenance, sanitation, and more.

These resources are there to assist you in your plant's ReCon efforts.

-

Read: Hotlist and Key Elements

-Now that you have familiarized yourself with the Road to Great Performance Tool (RGP), the next step is to develop a hotlist based on the tactics and your responses in the RGP tool.

So, what is a Hotlist?

- The Hotlist is a list of resource conservation opportunities that have been identified as potential opportunities and/or projects.

- The Hotlist line items are pulled from the pool of action items identified via the ReCon tools based on the ReCon team’s judgment for what should be a priority. Whilst it is not limited to the RGP tool, tactics from RGP tool responded to as 'No' or 'Not Optimized' can form the basis of your hotlist.

- The Hotlist should constantly be evolving as line items are completed and new opportunities are added.

Review of Key Elements

A balanced Action Plan is essential for success

- Commit most of your resources to A and B priorities

- Do not ignore the “C” priorities — there may be significant risk or opportunity in these areas

- Avoid over-commitment

Ensure Action Plan resources are within the capabilities of the site

- No more than 20 action planners in a year

- Be aggressive but be flexible

Keep it to one page

- Easy to communicate and review

- Promotes awareness throughout the organization

- Leave the technical solutions to the action teams

- Keep score, keep your commitments

Evaluating the Results

- Review and/or complete the Road to Great Performance of your plant

- Note that partial compliance is an opportunity

- Develop a Master List of opportunities

- Assign priority letters to each — A, B, C, D

- Sort opportunities by priority

- Create your “ReCon Hotlist” by selecting the 10-20 best opportunities for your site

- Estimate cost, ReCon impact, and payback for each

- Work with key players at your site to develop detailed action plans

Remember: Don’t work on too many items at once. Select fewer items and get them completed more quickly.

Use the RTGP action planning template to get you started with your hotlist and action plan. In the next section you will learn more on using the hotlist to action plan.

AOP: Annual Operating Plan

-

Read: Action Planning

-Creating action plans is one thing, but execution is key.

Executing the Action Plan

There are 3 main steps to executing the action plan:

- Create detailed action plans for each project by forming teams to finalize the plans. Make sure you're using the provided action planner. Always involve site employees in the action planning to give them ownership and accountability in the process.

- Present the action plans to the larger group. There should be between 5 and 7 action steps. Identify the resources and responsible parties that are required.

- Verify that the site management supports the plans by getting the site manager's feedback.

Key Elements of Focused Action Planning

Below are the main elements to include in your action plan:

- Define key drivers — know which metrics are impacted by the plan

- Quantify opportunities — measurement counts

- Establish goals — what will you accomplish

- Fill the performance gap

- Tie rewards to results

- Calendarize performance — add due dates for tasks

Review the RGP & Action Planning Training Deck to understand how to develop a hotlist and action plan using the tactics identified in the Road to Great Performance Tactics.

You can also download and use the generic action planning template for your identified tactics.

-

Review: TakeOn ReCon

-Download and use this document that asks what YOU are doing every day to TakeOn ReCon. Feel free to print it out and post it by your desk as a daily reminder. These are 10 examples of how you can improve ReCon on on site.

-

Decide: Plan First Tasks

-Now that you've had a chance to review the Road to Great Performance and the Best Practice tool, take a subsection: Which tactics have you seen within your plants? Which haven’t you seen used at all?

Think about which tasks you can start that will have an impact now. Focus on easy tasks that will produce quick results.

Remember to use the Takeon ReCon to get you started.

-

Discuss: Taking Action Now

-Share two or three things you chose to try now and describe how you'll get started. Check back to see what ideas your colleagues have for taking action now.

-

Download and Review: Next Steps and Commitments

-So what's next?

- Download and save the ReCon checklist to get a good start on all the tasks for ReCon.

- Measure your progress in completing ReCon Program Basics and establishing your first steps as a ReCon Team lead/member.

- Click the boxes in the document to check and track your progress. It's a word document so you can add additional items you want to track.

Remember you can always refer to the Global Sustainability - ReCon Global Brain Site for tools. Best practice is to bookmark this page and refer to it as you progress on your journey so you are not "reinventing the wheel." The document below provides a summary of the tools reviewed in this course and links as well for your reference. Note profilers are reviewed in our Water and GHG fundamentals ReCon courses.

-

-

Power Walk

-

Read: Power Walk / Walk, Watch, and Win!

-So what is a Power Walk (also often called Walk, Watch, and Win!) and why should you prioritize it? A Power Walk is performed among processing and packaging groups and provides a consistent way to maintain performance across production lines and identify ReCon issues.

Regular, structured walks throughout the plant allow you to catch issues fast and not days or shifts later. You can make sure any issues are communicated to operators in a timely manner and solutions are put in place.

Timesaver tip: Make the Power Walk one continuous route to eliminate backtracking and loss of focus.

Historically, this was completed using paper and pen or Excel, but more and more sites are now leveraging technology.

-

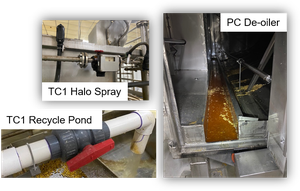

Benchmark: In Real Life

-Lynchburg completes a daily Power Walk, completed by the ReCon point person and backfill. They walk through all the processing lines, packaging department, control room, and boiler room, looking at water, steam, natural gas, electricity, oil loss, air compressors, and nitrogen.

Here are some big learnings/findings:

- Peelers (> 15 GPM) - savings of $147.45 per day

- Corn wash halo spray - savings of $162.20 per day

- Push water recycle pond - savings of $52.00 per day

- Fryer containment skids, de-oilers (leaks or SX) - savings of $100.00 to $20,000.00

- Nitrogen use - savings of $48.00 per day

As you can see, the savings add up. What may seem to be a small issue can add up to a huge loss over time.

Similarly, the bottling plants in the United States are completing their "Walk, Watch, and Win!" rigorously to ensure their ReCon performance is not slipping by catching and correcting anomalies more quickly. Operating a reverse osmosis system with a slightly lower efficiency could have a significant impact on water consumption, and therefore on the operating costs of the plant.

- Peelers (> 15 GPM) - savings of $147.45 per day

-

Document: Your Power Walk

-Whenever possible, go digital and use your tablet during your Power Walk.

Benefits:

- Elimination of paper and pencil checklist

- Standardization from site to site

- Organization of content in a way that facilitates process

- All data gathered in a central location

- Easy way to visualize information and highlight follow up actions for sites

Below are downloads of Excel versions of a Power Walk checklist and Walk, Watch, and Win! Consult your sector/region ReCon lead to learn if there is already a localized version that you could use. If not, start with one of these files below and create your own Power Walk. This is one of the quickest ways to start improving your ReCon performance. Really!

-

Discuss: Observations

-If you came across the following equipment during a power walk would you be able to spot what's wrong in these pictures? Identify in the discussion what's wrong.

-

Complete: Check for Understanding

- -

Read: Beyond PepsiCo: Green Teams

-What is a PepsiCo Green Team?

Green Teams are a volunteer grassroots movement to create a sustainability culture throughout PepsiCo & our communities because we care & it’s our planet.

Who We Are: Passionate, inclusive, positive, encouraging, small acts have a big impact

Who We Are Not: Green extreme, shaming/guilt trip, ultra-green

What We Do: Green our workplaces, spread knowledge, engage employees, positively impact communities, connect and contribute to PEP P+ goals

Green Teams can take many different forms at PepsiCo

- Office Location: Team is centered around one physical office location, but can also encompass employees who work remotely or at nearby manufacturing/warehouse locations

- Plant/Warehouse Location: Teams at manufacturing/warehouse locations can form their own teams or participate in activities (e.g. virtual events, community clean-up) with office-based or regional teams

- Business Function: Organized by business function rather than physical location—the business function could be spread out across multiple work locations or sit in the same location. E.g. PBNA Marketing team

- Virtual team: Green teams do not have to have a physical location, they can be work-from-home employees within a common geographic area

Top 10 Reasons to Start or Join a Green Team

- It's fun!

- Get to know new, like-minded co-workers & senior leaders that you might not interact with in your daily job.

- Introduce a new sense of purpose into your day-to-day work.

- Develop new skills outside your primary job. Just because you are not part of the communications team doesn’t mean you can’t work on a Green Team newsletter.

- Develop leadership skills & have ownership over a project or workstream.

- Unleash your inner-creativity. A trash fashion show? Water bottle decorating contest? Bring on the wacky, goofy ideas!

- Small Acts=Big Impact. Did you know recycling 32 plastic bottles saves enough energy to power a 60-watt light bulb for an entire year? YES! You have the power to make a difference.

- Have a positive impact in your local community.

Common Questions about Green Teams at Manufacturing Sites

Do Green Teams work on environmental compliance?

- Historically, Green Teams at some manufacturing sites were focused on environmental compliance. However, this is now handled by Environmental Health & Safety Teams, NOT Green Teams.

Are Green Teams the same thing as a ReCon team?

- ReCon teams at PepsiCo (as you are learning in this training!) focus on reducing the impact of our operations (energy, water, waste).

- Green Teams go beyond reducing the impact of our operations. Green Teams at PepsiCo are a volunteer team of passionate people coming together to make a difference in their workplace and community.

- They provide education to colleagues on different sustainability topics, simple tips to be green in the workplace and at home, community engagement opportunities to make a change, and more.

- All employees and all ReCon teams are welcome to participate in Green Teams!

In the next lesson, we will talk about how YOU can get involved in PepsiCo Green Teams!

-

Read: How Can You Get Involved in a Green Team?

-1. Join the distribution list for a regional Green Team

- Visit the Green Team Hub to find contact information for a Green Team in your geographic area.

- Join the Green Team distribution list, connect with the team, and participate in activities (e.g. virtual events, local community clean-up).

2. Start your own Green Team

- If a Green Team does not currently exist at your location, you can start one!

- On the Green Team Hub, you will find the below resources that will help you start a Green Team:

- How to Start a Green Team Playbook

- Green Team Initiative Library of Best Practices (1-pagers on activities/events from existing Green Teams)

- Link to Yammer page to connect with like-minded colleagues

- Green building resources, PPT Template, PepsiCo Green merchandise ordering platform, & more!

Download the attached PDF (and share it with colleagues) as a reminder of the PepsiCo Green Team program and how you can get involved.

-

ReCon Program Basics - Capstone

-

Final Activity

-

Attend: Capstone Call

-This event will take place on the last day of the course - you will receive a zoom call invite to join the session.

Agenda:

- Review takeaways

- Group discussion of quick wins and successes

- Answer any questions

- Group discussion of next steps - what do you want to learn next?

-

Recommended for: Anyone who wants to expand their knowledge in resource conservation, or who is already involved in ReCon but wants to expand expertise and tools set.

Required for: Manufacturing site ReCon lead and ReCon region lead and ReCon team members

There are No Pre-Requisites to take this course. This course is available in English, Spanish, Portuguese, Russian and Chinese. Prerequisite for most ReCon courses

Enrollment in the course is easy. If you have taken a course with us previously, simply click on Enrol Now for the date you want to take the course.

If you are a new student to CorpU, complete the registration form using this link: ReCon Training Registration Form.

You will receive course details and login information 1 week before the course starts.